Outside-in Process Q&A

On Friday, I presented an overview of outside-in planning to a consulting group. I love the questions when I present. The reason? The dialogue helps

On Friday, I presented an overview of outside-in planning to a consulting group. I love the questions when I present. The reason? The dialogue helps

The answer to a simple question of why do consumer products manufacturers not use retail data in the management of the supply chain?

During August, I moved and I spent the weekend painting my new shed with gloppy, wet deck paint. As I methodically pivoted the roller to

Last week, I spoke at the CPHA supply chain conference in Philadelphia, Pennsylvania. (This was the inaugural supply chain event for the Consumer Healthcare Products

Mine sweeping is essential to warfare. Soldiers use special devices to detect underground mines and disarm them, keeping them from exploding before they cause

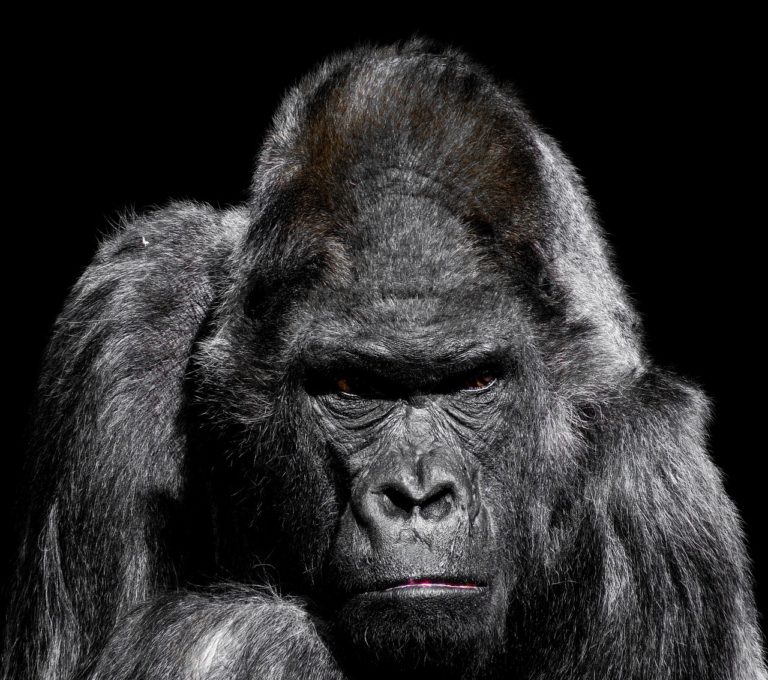

Within a supply chain organization there is turmoil. The enlightened leader knows that the efficient silos do not create the most effective supply chains; however,

The 2016 US presidential political contest was brutal. Emotions are still quite raw. I hated it. When emotions run high, everyone loses. Unfortunately, I think

It was November. I was speaking at a client site. The topic was customer-centric supply chains. We started the morning by asking attendees to share

A River Runs Through It is one of my favorite films. The scenes directed by Robert Redford are beautiful. As the story unfolds, a family with

Functional silos define today’s supply chain organization. The silos compete. They lack alignment, and a result, cannot effectively collaborate. This lack of alignment is an