Decline In Performance in Consumer Products. Are You To Blame?

On Thursday morning, I began an engagement with a food manufacturer attempting to drive “Supply Chain 2.0.” When I asked for a definition, the phone

On Thursday morning, I began an engagement with a food manufacturer attempting to drive “Supply Chain 2.0.” When I asked for a definition, the phone

I was on my way to Peru. I scooted into an aisle seat and sat beside a stranger. He begrudgingly let me slide my bag

Last week Walmart announced the closing of 269 stores and the layoffs of 10,000 employees. In addition, Macy’s announced the closure of 36 stores and

Definition Bookends: To be positioned at the end or on either side of (something). Colgate. Procter & Gamble. Kimberly-Clark. Unilever. These consumer products global leaders

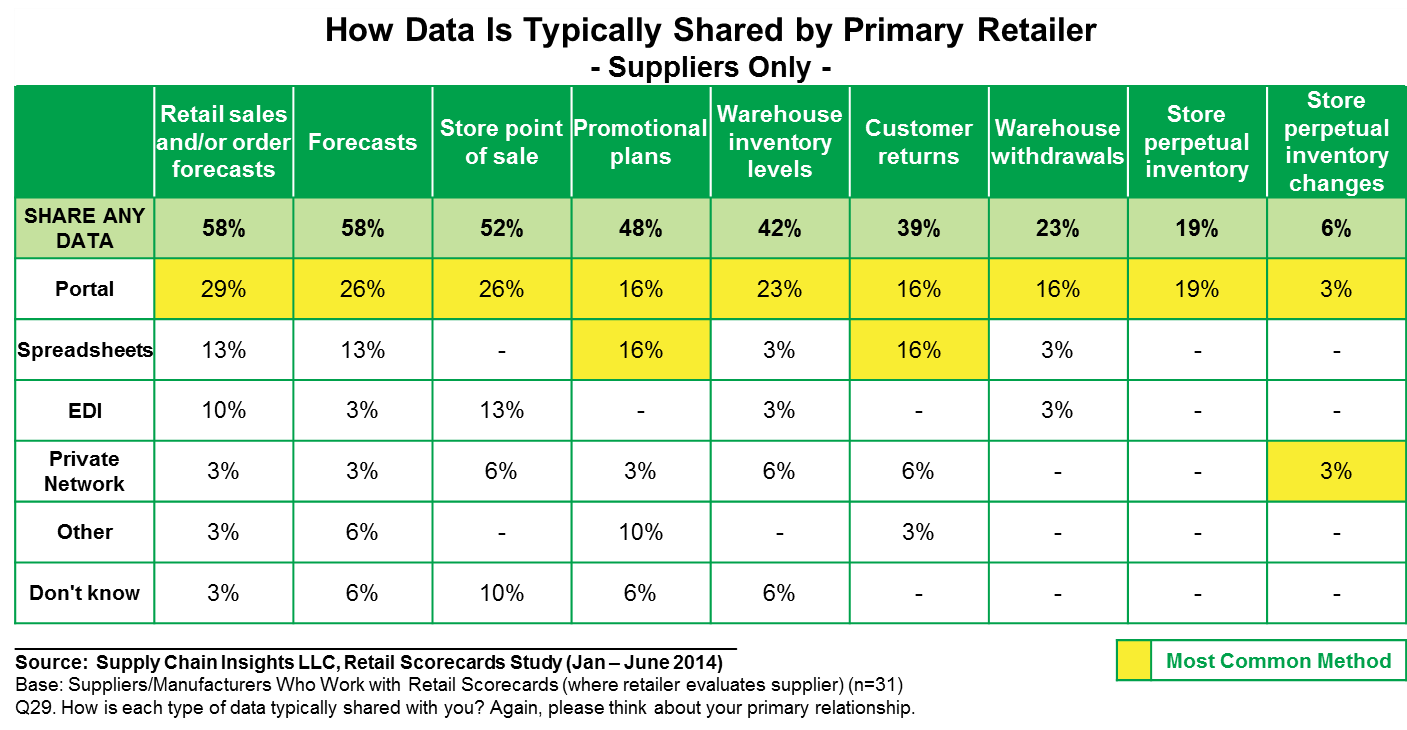

Definition: Brass tacks are a type of pin or nail. The phrase to come (or get) down to brass tacks is sometimes used idiomatically to consider the basic facts of

It is pretty on the shelf, but it can be a problem for the sustainable supply chain. In fact, unsuspecting consumers would never guess at the issues that

This morning I am sitting at my kitchen table, sipping coffee, writing a report. The coffee is good, the sunflowers are blooming on the deck

Most people assume that great bus drivers (read: business leaders) immediately start the journey by announcing to the people on the bus where they’re going—by

Rising commodity prices. Tight margins. Flat growth. To me, this sounds like it could be a stimulus plan for supply chain excellence. However, I am not sure.

It is cold in New York. My feet are tired, but I have enjoyed the first day of the National Retail Federation (NRF) Big Show. (Twitter