Social. Mobile. Sensors. 3D printing. The Internet of Things. The list goes on and on.

The atoms and electrons of the supply chain are changing. My mind is spinning with the possibilities. Transmitted perfectly, replicated indefinitely; and with a one-time investment in network infrastructure, a digital task performs well with zero marginal cost. As a result, new data types move quicker and more accurately, with lower levels of investment.

I am passionate about the topic of the digital supply chain, and I apologize in advance for the length of this article. To enjoy the spirit of this post, get a cup of coffee, and curl up on a couch with your tablet and let your mind imagine the future.

Reflections

The third Supply Chain Insights Global Summit is over. We are starting to plan for next year. It is an agenda designed by supply chain leaders for supply chain leaders. The conference is always a lot of fun.

At the conference I encouraged the attendees to network with each other, to build a guiding coalition, to redesign supply chain processes for the Supply Chain of 2025. To deliver on the promise requires a guiding coalition of thought leaders. Building the inertia is my goal.

For the supply chain leader tackling the digital supply chain, the clock will tick quickly, but progress will happen slowly through deliberate actions. On the journey for the supply chain leader, time is irony personified. It is so much work to make small incremental improvements. The question on leaders’ minds is, “How do I make the most improvement?”

As the conference agenda wound to a close, I stood alone on the stage thinking about outside-in processes to make the digital pivot. I feel strongly that it needs to happen. Why? Stuck on a performance plateau, supply chain leaders are unsure what to do. As shown in the 2015 Supply Chains to Admire report, over time, top performing supply chains plateau. As a result, companies like AstraZenca, BASF, Colgate, Reckitt Benckiser, Seagate, and Taiwan Semiconductor outperformed their peer group in the period of 2006-2014, but sustained improvement becomes more and more difficult. As supply chain improvement plateaus, it requires a rethinking of processes to get to the next level. I think the answer is an investment in digital processes.

How Do We Make Progress in This Overhyped World?

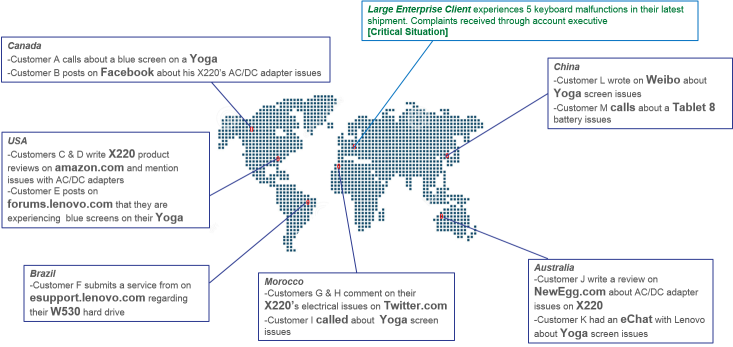

There is tension. Navigating corporate politics is an ongoing challenge for the supply chain leader. At the conference the remarks of Anthony Volpe from Lenovo struck a chord. He spoke on the use of global sentiment data to sense and improve customer experiences. In his opening he remarked on an interview with his board. He reflected on his emotions when his CEO threw down a Harvard Business Review article on Big Data and customer-centric sentiment/social information and asked Anthony how he was going to do it.

The problem is that we, as supply chain professionals, are often at the intersection of overhyped big ideas by consultants/press and the reality of today’s processes. The use of social data in supply chain processes is just beginning. It is one form of digital data. Reality? We want to use social data; but, we do not know how. There is no place to put social data in today’s supply chain processes. However, the overhyped perception by many executives is different. Executives believe it should be easy. It is not.

Figure 1. Lenovo’s Use of Customer Sentiment Data

Anthony’s challenge? We easily navigate the digital world in our personal lives, but enterprise software is not digital. There is no place to put the data. This is the unfortunate reality of the journey for the supply chain leader trying to make the digital pivot.

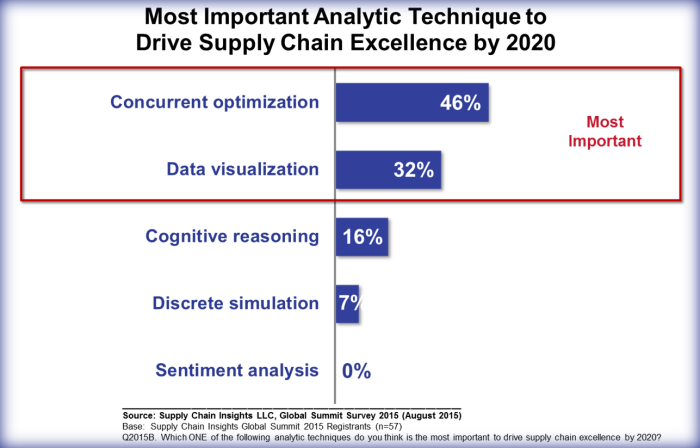

Figure 2. Current State of Use of Sentiment Data in Supply Chain Processes

The tension? Today, most companies are spending 1.7% of revenue on technologies which will quickly become legacy in the race to define digital processes. Ironically, while there is a lot of talk, the organizational momentum is investment in legacy applications. There is little movement on the creation of digital processes.

Let’s take an example. The concept of text mining or social sentiment analysis is not on the radar for most supply chain professionals. Instead, social data, if used at all, is examined by the team in the digital marketing department, but it is seldom shared with the supply chain group. In the evolution of today’s analytics most companies are evaluating concurrent optimization of transactional data. We are just beginning to understand how to use sentiment data and new forms of analytics. It will evolve in the next five years. As shown in Figure 3, the period of 2015-2020 will be about analytics. However, the period of 2020-2025 will build on a confluence of disruptive digital technologies. Making the digital pivot will embrace all of these disruptions together to drive innovation and new business models. The confluence will drive the evolution of digital outside-in processes.

Figure 3. Confluence of Disruptive Technologies on Supply Chain Processes

Why Do We Need Digital Processes in Supply Chain?

While e-commerce was the driver of growth for Retail and Consumer Products in the last decade, digital transformation is the driver for the next decade. To better understand this, let’s more closely examine seven facts:

- Companies Want Adaptive Systems. Today’s supply chain processes respond. They do not sense. Because they cannot sense, they do not adapt. Global markets are both concentrated and dispersed. They are dynamic. Without sensing, and market-driven outside-in processes, the organization is out of step with the markets they serve.

- The Supply Chain Is a Nonlinear Complex Adaptive System That We Are Modeling Using Linear Optimization. The first and second generation of supply chain technologies used linear optimization. Based on technological capabilities at the time, it was all that we could do. However, today we know the supply chain is a complex system with nonlinear relationships. The good news is that the new forms of prescriptive and cognitive analytics help to model nonlinear relationships. The bad news is that they are new evolving requiring co-development. New forms of analytics–cognitive computing, artificial intelligence, rules-based ontologies, pattern recognition, combinatorial math– promise new answers. The use of these new forms of analytics, in combination with relational and non-relational database architectures, offers new opportunities.

- Customer Data Has Never Been More Available. There Is a Gap in Our Ability to Use It. With the evolution of social, mobile, and web-based technologies, customer data has never been more available. We want customer-centric supply chains. The irony is that we are unable to use it. The use of unstructured and semi-structured customer data requires new techniques and processes.

- Digital Data Moves Quickly at the Cadence of Business. Enterprise Systems Move Slowly at the Speed of Transactions. Our current enterprise solutions are slow and inflexible. They cannot move at the cadence of business. The world has become digital. Supply has not. We are out of sync with the digital world.

- Inside-Out Versus Outside-In. The traditional supply chain depends on orders and shipments. Both signals have data latency (out of sync with the market) and accelerate the Bullwhip Effect. MRP and DRP logic uses order and shipment data permeating the Bullwhip Effect. The movement to outside-in processes has the potential to reduce waste and prevent the distortion of signals between nodes in a value network.

- CRM and SRM Are Not the Adapters to Build the End-t0-End Value Chain. Customer relationship management (CRM) and supplier relationship management (SRM) are enterprise applications. They are not suitable connectors for B2B networks. The connections to B2B networks need to be based on trading partner synchronization and harmonization of data through the use of canonical infrastructures.

- Opportunity with New Technologies and Approaches. Last, but not least, and probably the most important point, is the opportunity through the use of new technologies and rethinking processes based on new thinking. It just makes sense to align the supply chain with the speed of business based on the voice of the customer.

Step 1: Redefine the First-Order Design Principle for Supply Chain Decision Support Technologies. A software developer starts with first-order design principles in the building of code. The first-order logic of a digital process is dramatically different from the traditional assumptions of today’s systems. As a result, outside-in software is not an extension of the traditional inside-out optimization from the first and second rounds of software evolution.

Today, supply chain software leaders struggle with the Innovator’s Dilemma. In 1997 in Clayton Christensen explained the tension. In the face of disruption, this dilemma is deadly. What happens? Successful companies put too much emphasis on the stated customer’s needs and fails to adopt new technologies or business needs. They miss the new market opportunity. It is illogical, but important. Eastman Kodak failed to make the digital pivot, and many software providers will fail as well.

In supply chain the Innovator’s Dilemma is alive and well. Supply chain software providers are struggling. Traditional commercial models focus on maintenance upgrade cycles and refinements of existing software. Business leaders do not know how to define digital outside-in processes. The inertia is incremental improvements to existing software. What needs to happen is a redefinition. It is a tough transition. However, it will define a new set of winners and losers.

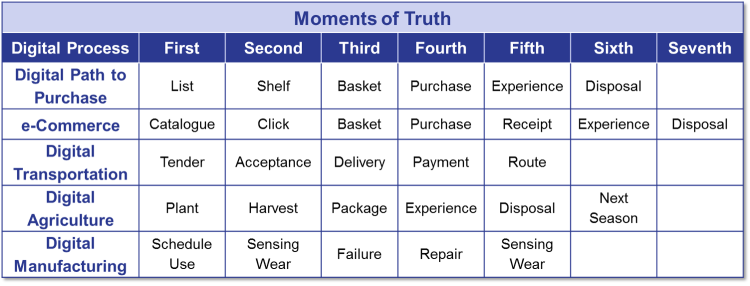

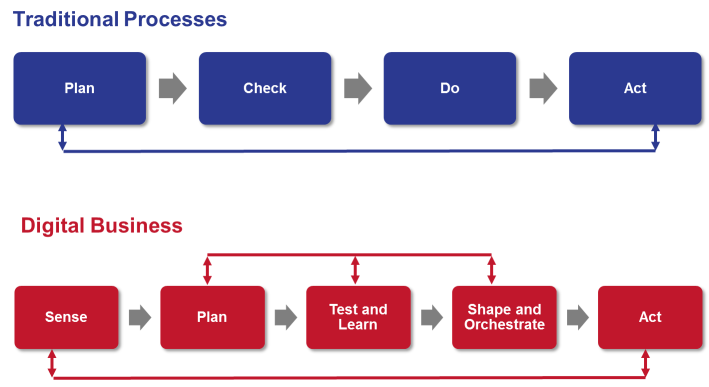

Step 2: Define the Moments of Truth and Build Test-and-Learn Strategies. For most companies the traditional focus is on the management of order to cash, procure to pay, and forecast to deliver processes. As companies build digital processes the moments of truth in the supply chain change. This enables the automation of test-and-learn strategies to flex and adapt at the moments of truth. In this blog post, I will apply this methodology and discuss the potential redefinition of three digital processes: Digital Manufacturing, Digital Path-to-Purchase, and Digital Agriculture. I could have picked a myriad of processes, but I am going to focus on these three to illustrate the points.

What is a moment of truth? It is an inflection point and a measurement of success. When companies do well at the moment of truth there is success. Meeting the goal of the moment of truth is black and white. At each moment of truth the supply chain either delivered, or it didn’t. For example, was the product on the shelf in the digital path-to-purchase process when the consumer was in the store? Or did the machine fail in the digital manufacturing process? Another example: was the product delivered on the delivery date? In the definition of corporate social responsibility we must also embrace disposal. Was the product disposed of in a way that meets corporate social responsibility objectives? The moments of truth for digital processes are outlined in Figure 4.

Figure 4. Moments of Truth

In addition, in the development and rethinking of these first-order processes, through the use of cognitive and prescriptive analytics, we have the opportunity to build test and learn processes. This can be continuous through the design of process hypothesis and continual test-and-learn strategies. Examples are:

- Retail Category Management. Was the assortment optimal for a market? Do test stores perform better than control stores?

- Digital Agriculture. Did the combination of seed and crop protection methods increase yield? How does it compare to test plantings?

- Digital Manufacturing. What improves the life of equipment? What conditions improves uptime? How can we schedule based on actual production capabilities?

- e-commerce. What drives a consumer to put an item in their basket on e-commerce sites? How can we improve baskets that are abandoned?

- New Product Sensing. Which markets responded best to a new product launch? What is the best combination of package and price to drive sales?

Figure 5. Contrast of First Order Thinking in Digital Processes

Step 3: Embrace New Forms of Data.

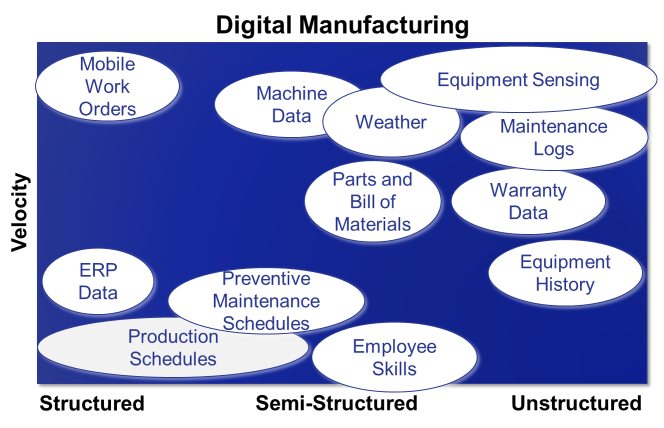

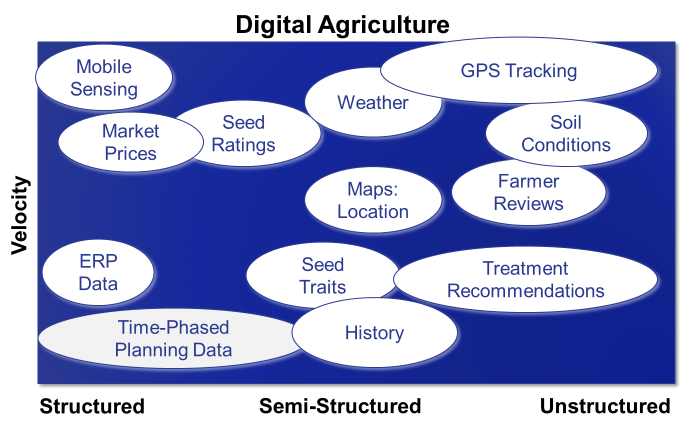

Digital outside-in process use structured, unstructured, and semistructured data. Historically we have lived in the world of structured data. We are just starting to envision a supply chain world that embraces the variety of data types. The redefinition reshapes our paradigms.

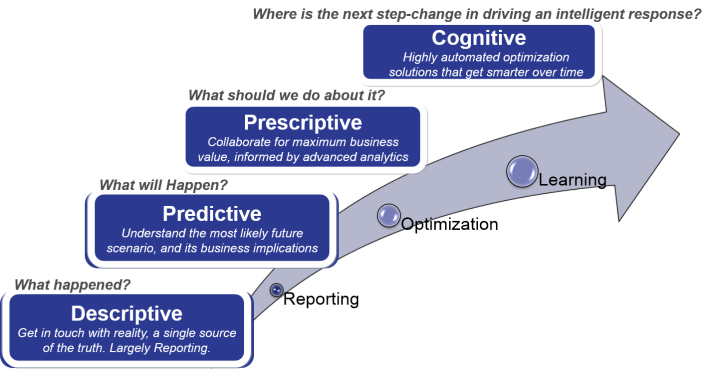

Fueled by structured data analysis, decision support tools today focus on optimization.However, as we embrace data variety the architectures need to embrace structured and unstructured data forms. This transition moves companies up the analytics maturity model shown in Figure 6 to embrace prescriptive and cognitive analytics.

Figure 6. Analytics Maturity

Step 4: Use the Power of New Technologies and Computing

The limitations of client-server or early hosting platforms held us back in the design of supply chain planning systems in the 1990s. As we harness the power of parallel processing in the cloud, we open up new opportunities of what is possible.

To envision the supply chain of the future, spend time to learn new concepts. Explore and understand the opportunities of non-relational databases, streaming data architectures, rules-based ontologies, cognitive learning, and new forms of sensors.

Step 5: Map the Processes Outside-in. Throw Away Old Paradigms.

Start with a white board. List the moments of truth and then brainstorm the data elements that can help to define the process analytics to improve the outcomes at the moments of truth. In the frameworks below, I share three example outputs from workshops that I completed.

-Digital Manufacturing. They typical manufacturing floor has many sensors and programmable logic controllers operating in isolation. What if these sensors could be read in real-time with the signals converted into production schedules? This is the definition of digital manufacturing.

Digital manufacturing continuously senses machine conditions and schedules maintenance schedules based on actual machine conditions. This is replacement of maintenance schedules based on mean-time failures. The benefit is greater reliability and increased productivity.

Figure 7. Digital Manufacturing Data Types By Velocity and Variety

-Digital Path-to-Purchase. The definition of digital path-to-purchase is the use of digital technologies to automate the generation of the list, the replenishment of the shelf, the analysis of the basket, the use of checkout data (point-of-sale and loyalty information), and sensing customer sentiment to better serve the shopper. Today, 5% of consumer products manufacturers have a digital path-to-purchase initiative.

Figure 8. Digital Path-to-Purchase Data Types By Velocity and Variety

-Digital Agriculture. Digital agriculture is the use of digital signals to improve yield and profitability of the farmer’s field. The use of unstructured data along with traditional structured data will enable new service models. Monsanto’s new investments in weather sensing are consistent with this vision.

Figure 9. Digital Agriculture Data Types By Velocity and Variety

I could go on and on, but I will stop. As you can see, I find digital supply chain processes exciting. If you do too, stop by your digital marketing team and start brainstorming. If you would like to brainstorm with supply chain leaders, join our Shaman Circle calls. These are monthly calls with supply chain leaders on specific topics like visibility and analytics. (And, you can join for free.) Just let us know!

These are my thoughts on this crisp fall day. I would love to hear from you!

About the Author:

Lora Cecere is the Founder of Supply Chain Insights. She is trying to redefine the industry analyst model to make it friendlier and more useful for supply chain leaders. Lora wrote the books Supply Chain Metrics That Matter and Bricks Matter, and is currently working on her third book, Leadership Matters. As a frequent contributor of supply chain content to the industry, Lora writes by-line monthly columns for SCM Quarterly, Consumer Goods Technology, Supply Chain Movement and Supply Chain Brain. She also actively blogs on her Supply Chain Insights website, for Linkedin, and for Forbes. When not writing or running her company, Lora is training for a triathlon, taking classes for her DBA degree in research at Temple or knitting and quilting for her new granddaughter. In between writing and training, Lora is actively doing tendu (s) and Dégagé (s) to dome her feet for pointe work at the ballet barre. She thinks that we are never too old to learn or to push an organization harder to improve performance.

Lora Cecere is the Founder of Supply Chain Insights. She is trying to redefine the industry analyst model to make it friendlier and more useful for supply chain leaders. Lora wrote the books Supply Chain Metrics That Matter and Bricks Matter, and is currently working on her third book, Leadership Matters. As a frequent contributor of supply chain content to the industry, Lora writes by-line monthly columns for SCM Quarterly, Consumer Goods Technology, Supply Chain Movement and Supply Chain Brain. She also actively blogs on her Supply Chain Insights website, for Linkedin, and for Forbes. When not writing or running her company, Lora is training for a triathlon, taking classes for her DBA degree in research at Temple or knitting and quilting for her new granddaughter. In between writing and training, Lora is actively doing tendu (s) and Dégagé (s) to dome her feet for pointe work at the ballet barre. She thinks that we are never too old to learn or to push an organization harder to improve performance.