Recently, I met with the Lyric team in New York. The room was small, and the conversation heated. Still, I listened intently as the Founder, Ganesh Ramakrishna, made a passionate case that businesses would profit from hiring a supply chain engineer and creating a supply chain engineer position within the company. The discussion made me think.

Fridays are my writing day. Each Friday morning, I make my pot of black coffee, put on my headphones, and begin writing. This morning, I had the opportunity to discuss the implementation of SCOR orchestrate with Peter Bolstorff, formerly at ASCM and now an independent consultant. He was a primary contributor to the SCOR DS model.

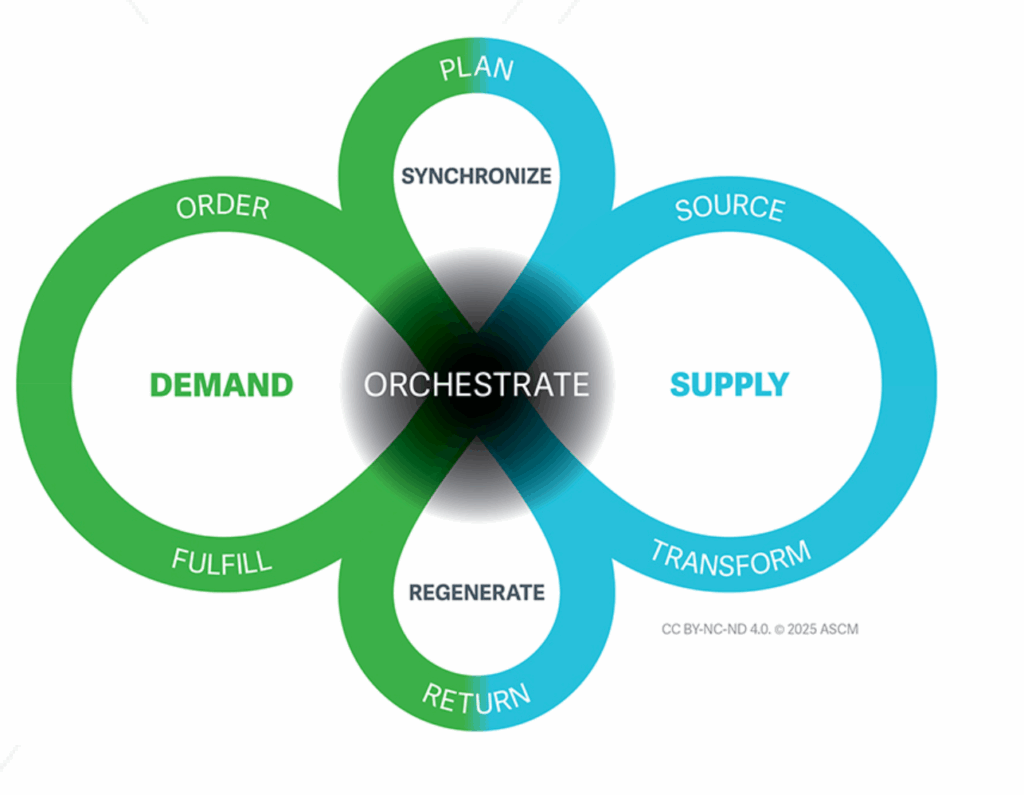

For those that have not followed the development of the SCOR DS model, the Level 1 processes are now orchestrate, plan, transform, order, fulfill, source, and return. Peter had three hours of road time, so we reviewed the model in detail. (Peter attributes his training on outside-in processes through Project Zebra as a defining moment to build the model in this manner.) We debated the term orchestrate in great detail. (You can imagine.)

We agreed that orchestrate was not a technology feature. Instead, it is a core organizational capability. (I wish that all the supply chain technology vendors leading with the term orchestrate would find all the references in their marketing copy and push the delete button.)

He ended the call by sharing a story on driving supply chain transformation using SCOR DS. As a strong believer in the Supply Chains to Admire methodology, Peter began this client engagement with metrics that drive market capitalization: growth, operating margin, inventory turns, and Return on Invested Capital (ROIC). After building orbit charts and analyzing market potential, he facilitated a session with his client to analyze organizational failure modes for 2025 performance.

His next step was to apply the SCOR Level 1 metrics and conduct a similar comparison. His conclusion? The biggest opportunity for his client is orchestrate. His recommendation to his client? Design a supply chain engineer role.

BINGO! I love it when great minds think alike.

Ganesh meet Peter. Peter meet Ganesh. Great minds are thinking alike.

Defining a Supply Chain Engineering Organization

I am a chemical engineer by background. Most academic programs offer materials, mechanical, computer, chemical, industrial, and electrical engineering, but I can find no school offering a Supply Chain Engineering degree. (Source Chat GPT.)

Many supply chain programs are housed in business schools and report through the marketing departments. (Which I think is amusing since supply chain management and marketing have such large gaps in alignment in the real world.)

I also find that Gartner’s analysis of supply chain management programs to not align with my personal experience. I struggle to find a good standard for measuring supply chain academic programs, and most of my manufacturing and retail clients frequently comment that students are ill-prepared to enter mainstream supply chain organizations. The concepts of a Supply Chain Engineering program appeal to me.

If you are a technologist, don’t fool yourself. Orchestrate is very different than concurrent planning. A technologist can enable orchestrate, but a business-led team needs to make it happen.

So, I went back to ChatGPT and asked for a job description for a Supply Chain Engineering role. Below, I share the output. I have crossed out the elements that I do not think fit and placed my comments in bold. I am interested in your thoughts. Here is a definition of orchestrate from the SCOR DS work.

Orchestrate Definition from SCOR DS

SCOR DS Model

Orchestrate encompasses activities related to the integration and implementation of supply chain strategies. This includes defining business rules and enterprise planning, managing human resources, designing networks and deploying technology, analyzing data, handling contracts and agreements, ensuring regulatory compliance, mitigating risks, advancing environmental, social, and governance initiatives, supporting circular supply chain practices, monitoring performance, and additional related tasks.

Courtesy of ChatGPT: A Job Description

A supply chain engineer is responsible for analyzing and improving a company’s supply chain processes to drive shareholder value. enhance efficiency and productivity. In this role, they design and build supply chain orchestrate capabilities. They develop strategies, collaborate with various teams, and implement solutions to optimize operations and reduce costs value chains by improving results on the balanced scorecard of operating margin, growth, inventory, and Return on Invested Capital.

A Supply Chain Engineer is responsible for designing, optimizing, and improving the efficiency of supply chain processes within an organization. They analyze data, identify areas for improvement, and implement strategies to enhance overall performance.

Key Responsibilities

- Managing Complexity. Analysis of product lifecycle and platform options, design of new product launch capabilities, and management of end-of-life processes.

- Design of Make, Source & Deliver Capabilities. Decisions on outsourcing, asset strategies, and time (order policy and cycles, manufacturing and supplier lead times, and route to markets) are made to strike the right balance between risk and opportunity. Risk should never be viewed in isolation.

- Definition and Management of Policy and Governance. Definition of contracts, strategic partnerships, supplier development, planning governance, and go-to-market strategies.

- Organizational Design and Building Supply Chain Core Capabilities/Knowledge Systems. Building supply chain acumen and collaborative systems. and workflow. Creator of career paths, mentoring systems, and development programs.

- Driving Innovation and Integrity in Data and Analytics Systems. Design of analytics systems to provide meaningful insights at the speed of business while driving innovation programs to test and learn the power of new analytic approaches.

- Alignment of Metrics to Maximize Value. Definition of benchmark and core capabilities, and alignment of reward systems to maximize value.

- Ethics and Governance. Policy and enforcement of ethics and rules of engagement. Definition of governance for returns, circular economy, and corporate sustainability.

Process Optimization: Analyze and improve supply chain processes to reduce costs and increase productivity.Data Analysis: Conduct data analysis to identify bottlenecks and develop solutions.Collaboration: Work with various teams, including Sales, Operations, and Customer Service, to implement supply chain strategies.KPI Development: Determine key performance indicators (KPIs) to measure supply chain efficiency.Documentation: Document procedures for supply planning and train team members.

Required Qualifications

- Education: Master’s Degree in Organizational Development, Systems Theory, Analytics, or Data Science. Bachelor’s degree in Supply Chain Management, Logistics, Chemical or Mechanical Engineering, or a related field.

- Experience: 10-15 years of leadership in building teams and driving supply chain excellence. Geographically aware. The ability to manage and lead diverse teams.

elevant experience in supply chain management or engineering. - Skills: Strong analytical, problem-solving, influence management, and communication skills. Ability to work collaboratively in a team environment.

Discussion

Some might say, “Isn’t this the role of the Chief Supply Chain Officer?” Or, “The supply chain center of excellence?” My reply would be, “Only 5% of companies actively design their supply chains, and when they do, the objective function is usually cost mitigation. We speak of moving away from functional metric reward systems, but it does not happen. We speak of managing complexity and lifecycles, but it does not happen.” The reason? Most organizations are focused on building stacks of efficient processes to improve functional metrics. Systems thinking and the management of the system as a whole entity is missing.

The charters of most Supply Chain Centers of Excellence are not aligned to orchestrate. The gap is that companies are unclear about what defines excellence. If the organization is mired in driving functional outcomes, the Centers of Excellence will never successfully drive an orchestrated agenda.

Wrap-up

A common belief is that supply chain management is a math problem to be solved through linear optimization to improve efficiency. We must move past cost and functional metrics.

In reality, value is created by focusing on physics and flow, applying systems thinking while actively designing organizational capabilities, network/supplier relationships, and asset strategies to support the key processes of order, fulfill, plan, transform, source, and return.

Many organizations are in the midst of a digital transformation or an analytics revamp using AI, natural language processing, and large language models. As shared in last week’s newsletter, success happens when programs are business-led, with strong analytics talent (data scientists and programmers) on the team, and a clear understanding of the organization’s mission and values, executed through holistic systems thinking.

To do this right, I agree with Ganesh and Peter that we need a Supply Chain Engineer. However, we must move beyond conventional thinking about efficient process optimization to unlock true value.

Would love your thoughts. ll the best on this cold and rainy weekend.