Imagine driving down a dusty road for years. One without any towns, road signs, billboards, or rest stops. Sounds boring, right? I agree. This is the world of the supply chain leader driving process improvement. The road to supply chain excellence takes time and patience. There are no clear landmarks or directional signage. Today, in organizations, there is a large gap between technology and process effectiveness. Here we examine some recent data on managing costs.

Imagine driving down a dusty road for years. One without any towns, road signs, billboards, or rest stops. Sounds boring, right? I agree. This is the world of the supply chain leader driving process improvement. The road to supply chain excellence takes time and patience. There are no clear landmarks or directional signage. Today, in organizations, there is a large gap between technology and process effectiveness. Here we examine some recent data on managing costs.

Sex, Sizzle and a Closet Full of T-Shirts

Technology implementations are the easy work. Driving value is much, much harder. While our closets are full of the T-shirts celebrating successful project implementations, it is tougher to acknowledge and reward process improvement work. I find most companies’ work plans stop with the implementation of Enterprise Resource Planning (ERP).

I get it. Implementing an ERP system consumes so much organizational energy. Technology vendors court and cajole through the selection processes, and large system integrator project management takes the wind out of any organization’s sails. Unfortunately, at the end of the project there is too little energy to drive process effectiveness.

Why Are We Not Better at Managing Costs?

Let’s take a look at some data. Last week we completed a quantitative study on Supply Chain Finance. The study had 56 respondents. Only 29% felt that they could easily get to cost data. For the majority in the study, getting to supply chain cost data was difficult.

For the supply chain leader, managing costs is job one. While we can argue about the road from cost to value, no one will debate that managing cost is fundamental ‘blocking and tackling’ for the supply chain team.

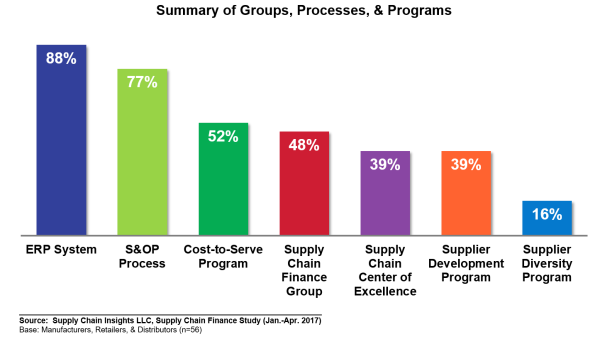

In a closer look at the data, 88% implemented an ERP system. As shown in Figure 1, there is also a high incidence of process focus work on S&OP, Cost-to-Serve, Supply Chain Finance, Supply Chain Centers of Excellence, and Supplier Development. Why is effectiveness in managing costs, and getting to cost data, so difficult? The answer lies in the multi-year work where we do not get T-shirts. It is the difficult task of building process effectiveness.

Figure 1. Characteristics of the Group Surveyed to Understand Supply Chain Finance

There are many groups who allege to have the answers. I am sure your email is full of consultant business development campaigns and sexy programs to drive success, but my take is that it comes down to leadership and grit. The road to supply chain excellence is not easy or well-understood.

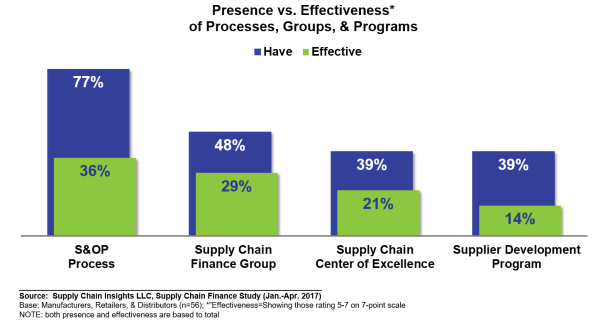

Figure 2. Process Effectiveness Analysis

Recommendations:

So what do you do? How do you drive better insights from the technology you have?

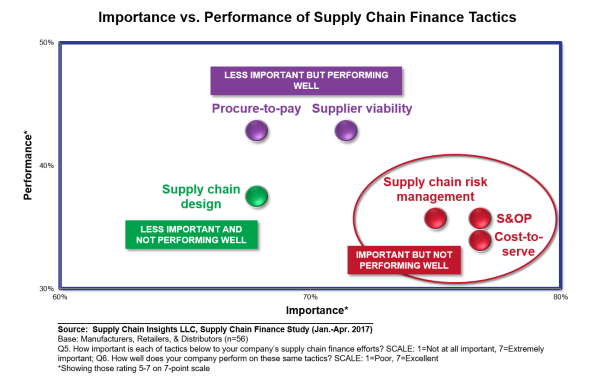

1) Challenge Traditional Thinking. The greatest cost opportunity lies in the cracks of the silos of the organization. Traditional thinking makes the organizational silos very efficient, but does not make the organization effective at managing costs. Push past the focus on transactional processes, like order-to-cash and procure-to-pay, and drive alignment and cost awareness in cross-functional processes like Sales and Operations Planning, Cost-to-Serve, and Supplier Development. This is not easy work. Be prepared to answer the question of which metrics drive the greatest value. Note the pattern in Figure 3. Companies rating themselves higher in ability to manage costs also rate themselves higher in Sales and Operations Planning, Supplier Risk Management, and Cost-to-Serve Programs.

Figure 3. Importance Versus Performance of Processes

2) Embed Network Design Work into Process Evolution. While many companies use network design tools for one-off or ad hoc processes, embed network design into S&OP, Risk Management and Cost-to-Serve. Plan by design. Make the work continual. The most variability stems from transportation, special requests, product mix, and customer service policies. Understand the impacts and drive process improvement.

3) Recognize that the ERP Implementation Is Not the End State. While many leadership teams believe great things will happen with the implementation of ERP, challenge the paradigm. Many companies have implemented technology for the sake of technology. The hard work lies in driving process effectiveness. My observation is that the greater success happens when there is a clear charter for the Supply Chain Center of Excellence, and when there is clear alignment between IT and the business teams. (Supply Chain Excellence is easier to say than define. Make it real for all.)

I hope this helps. For more on this topic, look for our Supply Chain Insights Newsletter next week. Each month we publish and share research reports openly with the supply chain community. We have written over 100 reports in the last five years. We hope that you use the data to help your team.

Failure: a Building Block for Success

As I enter my fifteenth year of trying to help supply chain leaders improve value through supply chain planning software, I answer a challenge by a reader on what is the value of an industry analyst. My reply centers on how I think we can help, and that it takes a village and I hope that he will help as well.