As I participate in technology briefings with vendors, I am trying to piece together the future of supply chain management. For me it is not clear. I believe that supply chain leaders are in the middle of step change in process innovation driven by not one, but a confluence of technologies. In each briefing, presenters bandy about the word “digital” like I throw Parmesan cheese on a pizza. (The more the better.) However, when I peel back the messaging in the briefings, it is not new. Most have the same technology, but with a new marketing spin. I sigh. Marketing hype annoys me.

On a side note, the reason that companies brief me is to “influence my ink.” They want me to write about them. This blog is now ready by 15,000 business leaders. Unfortunately, many technology companies only value analysts and influencers if they “write good stuff.” (And the definition of ‘good’ for this audience is positive comments.) Many technologists mistakenly believe they can “buy my ink.” This makes me laugh. There are many young analyst relations specialists asking questions. Here is one I received this morning from an Indian Systems Integrator, “Interesting read from your blogs always. How can we have your partnership to have mentioned in your blogs? We would like our capabilities to be seen and heard by user end folks. Your suggestions and advice would definitely be helpful.”

Yes, I am independent. I write for the business leader. My views are my own, and I think teams read my blog for the honesty. No one can buy my ink.

Driving Innovation

Process innovation is tough for companies. While new technology options abound, most companies are late adopters, saddled with limited budgets and the need to meet fixed Return on Investment (ROI) thresholds. As a result, the focus of projects is on yesterday’s technology stack of ERP/APS/CRM and SRM. These technologies improved the efficiency of functional processes, but they failed to improve overall supply chain effectiveness. (My point of view is that Supply Chain Effectiveness is improving process responsiveness for customer service while driving a positive change in Return on Invested Capital and Price to Tangible Book Value of publicly traded companies.) What I do know is that 88% of companies, stuck at the intersection of operating margin and inventory turns, struggle to drive improvement at the balance sheet level, and that user satisfaction with the traditional technologies is low.

My Insights on Digital Transformation

Today it is raining. It is one of those days when rain comes down in buckets and flows in sheets in the air. Sitting on the 15th floor of a high-rise apartment, I am writing a research report on Digital Procure-to-Pay. One of my insights is that there is a radical difference between automation and digital transformation. It is also clear to me from the research that most of today’s focus is on automation, not digital transformation. My goal for this blog post is to ensure the value proposition of digital transformation in value chains is not lost in nebulous discussions. Let me explain. When we automate, technology makes the existing process more efficient. In contrast, when we digitally transform, we ask “What is possible?” This includes disintermediation, changes in routes/methods, and use of different forms of data and advanced analytics. The team who is digitally transforming is questioning the atoms, electrons and flows of today’s processes.

- Atoms. Can substrates be manufactured with yeast? What is possible with reclaimed materials? The possibilities with 3D printing?

- Electrons. What does planning look like with cognitive computing? Is there a need for manual manipulation of master data with the evolution of artificial intelligence? Can an ontology enable process automation? Can we share resources/assets within a community (like Uber)? What is the role of hyperledger? How can Internet of Things (IOT) transform processes?

- Processes. Should goods flow through distributors? Or directly to customers with layered value-added services? What does an outside-in process look like? How can new technologies help to sense true demand?

I could go on and on, but I think you can see the difference. Companies pushing digital transformation road maps understand that the answer to the future is not in the automation of traditional supply chain processes.

The tough part is that we are still in the middle of process automation. There is much still to do. Business users question when to stop automating and when to start driving a digital transformation. There is tension.

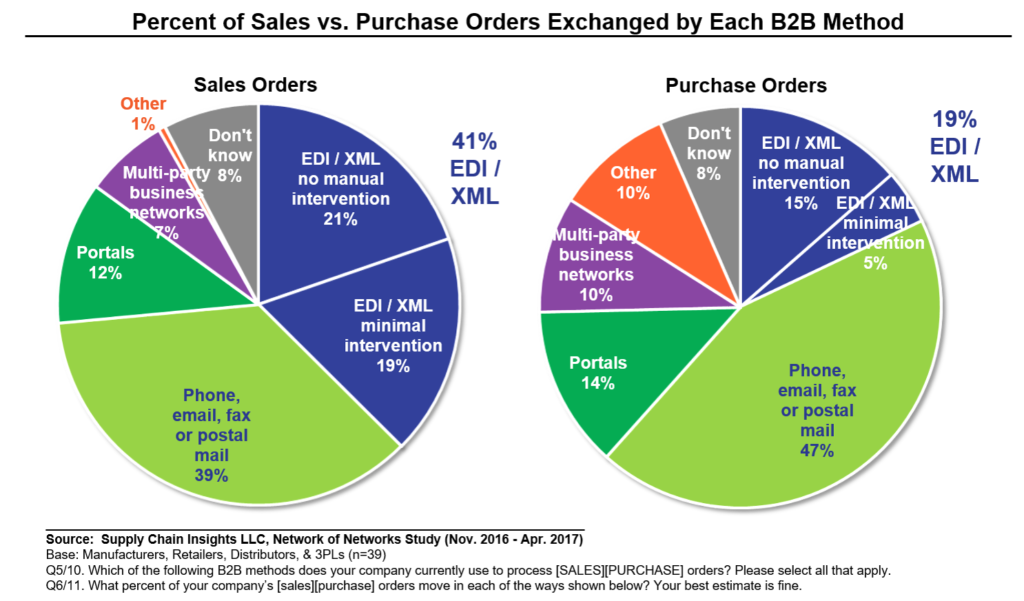

Let me give you an example. The movement of sales orders and purchase orders hands-free, a goal of the 1990’s, as shown in Figure 1, is still low. We are more automated in the area of sales orders than purchasing, but most companies want to outsource these transactional systems. I find when companies do business process outsourcing that they go backwards, not forwards, creating issues in achieving supplier development goals.

Figure 1. Current Order and Purchase Order Processing

So, when do we stop automating yesterday’s processes and drive a redefinition? When do we declare that technologies like portals only make us feel good and don’t drive much value? Notice in Figure 2 that the use of portals (a passive form of communication) is twice the usage of B2B networks.

Figure 2. B2B Methods

I think that it takes the building of a guiding coalition of business leaders, and that in the process, we need to hold ourselves accountable to some basic principles:

- The efficient supply chain is not the most effective.

- Automation is not the same as a digital transformation.

- Process innovation is different than process improvement.

- It cannot be technology for the sake of technology. We must focus on value.

- We do not have best practices. Instead, we have historic processes.

To move forward, I am convinced that we must define the value proposition of digital transformation for the industry. This is why I am facilitating share groups, doing research, and holding the Supply Chain Insights Global Summit. In the process, I must constantly sidestep the high-testosterone, hard-charging sales people, the marketing teams wanting pretty ink, the fast-talking consultants, and the conservative IT traditionalists. (I like a challenge. )

To move forward, I am convinced that we must define the value proposition of digital transformation for the industry. This is why I am facilitating share groups, doing research, and holding the Supply Chain Insights Global Summit. In the process, I must constantly sidestep the high-testosterone, hard-charging sales people, the marketing teams wanting pretty ink, the fast-talking consultants, and the conservative IT traditionalists. (I like a challenge. )

My goal is to work with business leaders to test technologies to deliver new business outcomes. I think that it takes a village. I hope you will join me in the effort.