The winds of change transform industries.

Does a digital transformation add value? Who knows? The answer is blowing in the wind because there is no standard definition. In the supply chain management industry, words swirl but lack definition. There are many claims but no clear definition.

Will we transform and improve supply chain planning systems based on AI? Again, who knows? In the sea of hype, there are few definitions but a lot of hand-waving. The industry is awash with technologists and consultants focused on selling solutions. Slick Willies, full of hyperbole, dominate. When you hear the term “AI” stop and ask for a definition and a use case. Side-step the hype.

Organizations need to push past pretty PowerPoint presentations to improve results, but in the industry, there are few good answers to the question of “What drives sustaining value?” This is my quest.

Background

I am an independent research gal. Unlike the bevy of pay-for-play podcasters and social influencers pelting us with opinions, my focus is on data and research processes.

Over the past decade, over 320,000 supply chain leaders have followed me on LinkedIn. (I give thanks for this!) Many followers answered my surveys, and over the past six months, I mined the data of fifty surveys to try to answer the question of “What we can learn from the past decade to improve planning?”

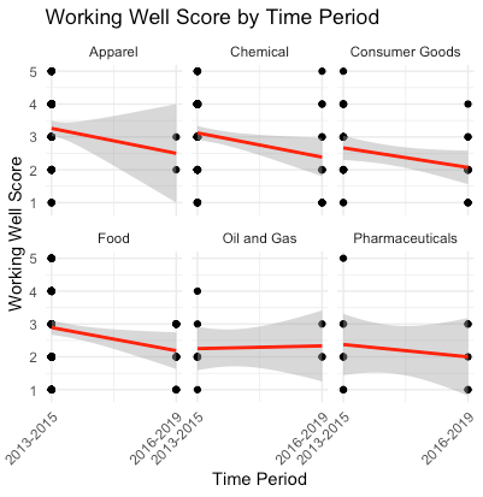

The survey responses were divided into three periods: 2013-2015, 2016-2019, and 2020-2022. (I thank the data science team at the University of Wisconsin for helping me understand the trends in the data.) Companies were more satisfied with their planning processes at the beginning of the decade than at the end of the pandemic. If this realization had been discovered and corrected, we would have been in better shape for the COVID period.

Rethinking Work

The winds of change should help us redefine work.

As companies consider purchasing new solutions based on better planning engines—machine learning, rules-based ontological frameworks, narrow AI, pattern recognition, large language models, and sentiment analysis— I ask for the use of caution. Today, most technology companies focus on better math in traditional functional planning taxonomy definitions. However, we need to challenge the base definition of supply chain planning. Improving the engines in conventional supply chain planning models is like putting sprinkles on a lousy cake. In contrast, my focus is, “How do we redesign work to improve outcomes?”

The answer is not better engines or even improved models. Instead, it is about evolving a decision-support architecture across roles to improve value. To do this, we must rethink supply chain planning and throw away functional models.

The decision to re-platform SAP ERP and focus on implementing HANA/Rise, is an opportunity. Many organizations ask me, “What is the value of best-of-breed supply chain planning approaches? Can I streamline contracting to have one throat to choke?” In an organization, this is an opportunity to open the discussion to have a meaningful path to redefine work while side-stepping the Slick Willies.

The first step is to get clear on the question of, “How do I drive value through supply chain planning?” For many, the results are disappointing. Organizations larger than 10B$ in annual revenue struggle with the costs of planning (payroll, benefits, software, maintenance, upgrades, and implementation services) and the gap in results. Planning teams number hundreds and even thousands of employees but cannot answer the question, “What drives a good plan?” When I ask, there is dead silence in the room.

In the redefinition of work and choices on improving decision support technologies, companies need to define the requirements for the system of record and the systems of insights. The systems of insights need a common data model with well-established flows and governance across all functions. The new engines and workflows require constant insights from market data to understand and sense variability. For an organization larger than 10B in annual revenue, this construct is very different from the traditional definitions of Advanced Planning (APS) and supply chain planning. If you agree with this statement, SAP Planning as a system of insight is not for you. However, SAP supply chain planning is an excellent system of record. You need both. The newer definitions of planning should be implemented to write to an SAP system of record.

What Can We Learn About the Redefinition of Work from the Research?

In over fifty quantitative studies from the last decade, we asked supply chain leaders to type their supply chains based on descriptors. As shown in Figure 1, in most industries, supply chain leaders’ belief in their supply chains working well fell over the decade and before the pandemic. The increase in variability played a significant factor in the decline. As a result, historic practices are not best practices. The industry never redefined planning for the global multi-national in a more variable world.

Figure 1. Working Well Scores by Industry by Supply Chain Business Leaders

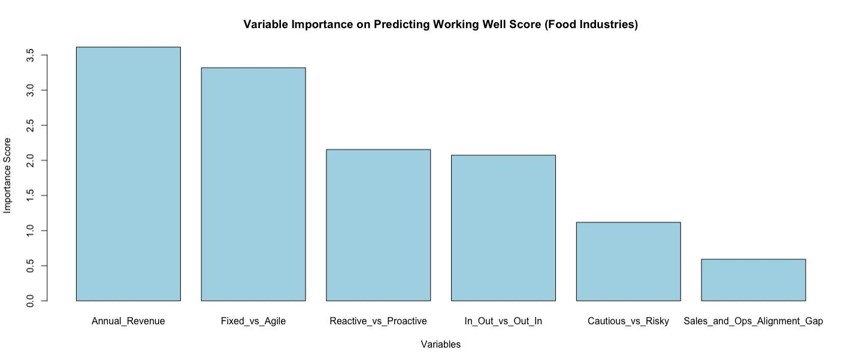

As shown in Figure 2, when companies are more agile, proactive, and outside-in, there is a better ranking of “working well” by supply chain professionals.

Figure 2. Relative Importance of Factors for the Food industry

For reference, each of the descriptors was defined in the surveys. Agile was defined as maintaining the same cost, quality, and customer service over time despite shifts in variability. Proactive was defined as the ability to sense and respond to market conditions.

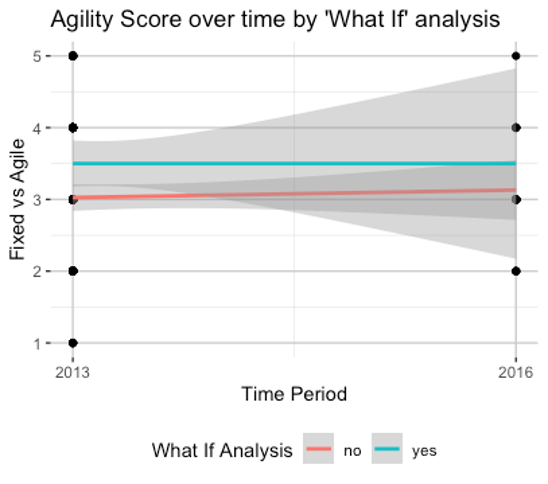

The most important factor in improving agility for make-to-stock industries was using “what-if analysis.” Companies that used what-if analysis in planning (blue bar in Figure 3) consistently rated themselves higher on working well scores. (Note: What-if analysis is not a strength of SAP planning. What-if analysis was lacking in SAP APO, and there is still a gap in SAP IBP. Tight integration of ERP to supply chain planning reduces agility.)

Figure 3. The Impact of What-if Analysis on Planning

So, what can we take-away from this analysis? Companies want to reduce costs and improve the value of planning. There are four alternatives. Here we use the research to rationalize the approaches:

- Tight Integration to ERP. One number Planning. This is the worst scenario. Companies focused on batch-job efficiency and tight integration score the worst. Planning should never be a single set of numbers based on an optimization engine. ERP data is enterprise centric. As such, it is latent and increases variability through bullwhip amplification throughout the organization.

- No-touch planning. The concept of no-touch planning is that planning engines and models are improved to the point that planners need not touch them. In the no-touch planning ‘camp’, market data and advanced engines are tested for superior results. As a result, companies can streamline their planning teams and depend more on model outcomes. Sounds good? The fallacy is that the insights from planning are more relevant when teams can use what-if modeling to better understand trade-offs. It is for this reason that I do not advocate no-touch planning. However, what-if modeling needs to be bounded with a goal in mind and clear guardrails of what good looks like. For example, modeling to improve forecast error and bias is less helpful than analyzing forecast streams for forecastability and forecast value added (FVA). Inventory analysis of safety stock is less effective than the analysis of form and function of inventory based on inventory value add/inventory health. Unfortunately, forecast and inventory data are touched too frequently with a reduced outcome.

- Better Modeling Using What-if Analysis. Some term the process of what-if modeling as a digital twin, while others describe it as network flow modeling. The goal is to test alternatives against well-defined hypothesis and definitions of supply chain excellence.

- Self-service Supply Chains. In the redefinition of planning for self-service supply chains, large language models and decision support systems using AI use market data to drive bi-directional orchestration options for business leader use. The planners become orchestrators cleaning data, modeling scenarios, and measuring success. In this alternative, the AI models proactively evaluate alternatives and provide insights to business leaders to work collaboratively using role-based workflows. This is where I would like the industry to head.

Why do we need to reduce the number of employees in planning teams? There are five reasons:

- Scarce. The industry has a shortage of supply chain planners. As a result, the number of vacancies is increasing with a spiraling of costs.

- Knowledge. In 8 out of 10 companies, planning is an entry-level job. The turnover is high, and the quality of the plan suffers. Organizations with planning tenure outperform.

- Expensive. Salaries, benefits, and support staff requirements increase as teams grow.

- Control/Influence. The goal is to align planning outcomes with the needs of the decision-makers. The use of intermediaries (the planners) slows the decision-making process.

- Better Decisions. Technological advancements can improve outcomes, but only if organizations are clear on “What good looks like.” To accomplish this goal, planning models need to be shared across the organization in a collaborative framework.

Conclusion

So, if you are wondering how to improve planning outcomes with SAP re-platforming, take advantage of SAP planning as a system of record while building a system of insights rich with what-if analysis and self-service planning options. The first step is aligning the organization with what good looks like in planning. Good luck in your journey and navigating the winds of change.

I look forward to your feedback on this blog post. Please put your comments into the stream.

The answer, my friend, should not blow in the wind.