Over the past two years, I taught over 600 students the principles of outside-in processes. I also taught the concepts to five technology companies. Some attendees expressed interest and stated, “Interesting Lora, but no one is asking for this functionality.” I bite my tongue, wanting to reply, “Did anyone ask Henry Ford to build a car? Or the Wright Brothers to fly at Kitty Hawk?” But, I quietly move forward.

Of course, their answer is correct. Manufacturers are not aware of this capability and, as a result, are not asking for it. The cycle continues since no technology company is marketing the idea. The industry suffers from groupthink. However, I persevere. Once you see a demand stream, you cannot unsee it. Companies are either driven to be innovators or followers.

I am excited that Kinaxis and o9 Solutions are now building the capabilities to analyze demand streams and drive bidirectional orchestration. The goal of the new approach is to maximize value using a balanced scorecard. In contrast, traditional solutions minimize functional costs. Each company’s approach is very different, but they are innovators.

Let me explain what this would look like. I will use a student’s homework from our last class to demonstrate the value.

Analyzing Flow

One significant advantage of in-memory processing, advanced visualization, and graph databases is the ability to visualize and respond to flow. A core principle of outside-in processes is to type demand streams and then align the demand characteristics with supply strategies as an output of the batch process.

The core principle items are not alike in characteristics or strategically equal in delivering value. Nor are all items forecastable. Forecastability issues grew post pandemic along with the bullwhip effect, but our systems did not adapt. Traditional systems forecast volume based on historical sales. All items move through the same optimizer for a time-phased output.

Biggest Threat to Innovation is Groupthink

I grow weary of supply-centric thinking and traditional risk management approaches. One of the greatest supply chain opportunities is redesigning demand processes to drive an adaptive enterprise. The growing issues of forecastability—market shifts, distorted history from the pandemic, or an extended product portfolio—are huge risks. The sad fact is that it is not recognized. As a result, I believe that the industry is guilty of groupthink.

An Example

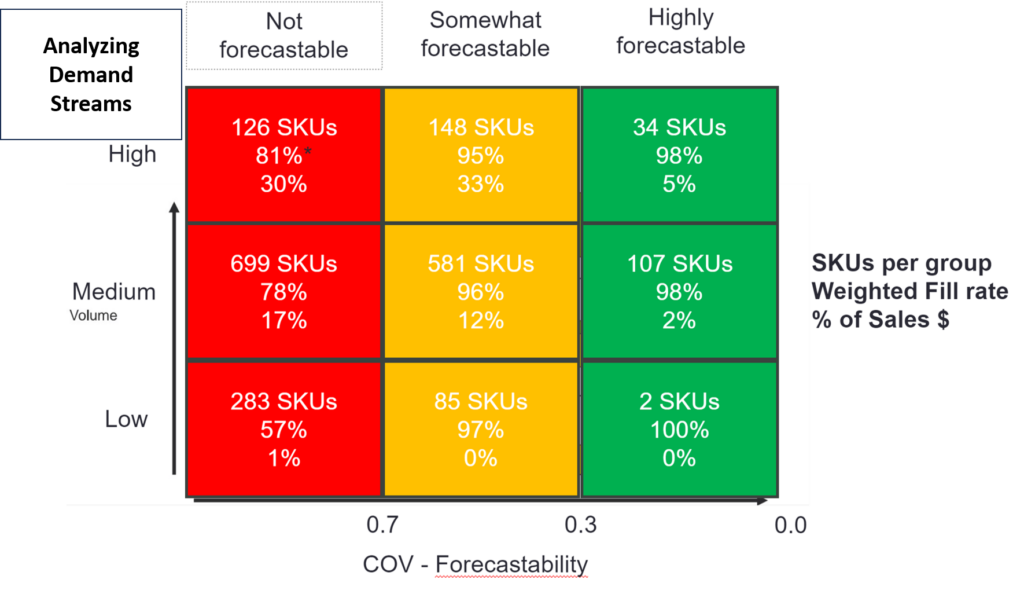

In the class, I ask the respondents to complete homework. One of the assignments is to plot forecastability by volume. A Coefficient of Variation (COV) greater than .7 is considered not forecastable, while a COV of .3-.7 might be forecastable with the proper techniques, and a COV less than .3 is very forecastable using traditional models. In the class, I was surprised at the number of items that were not forecastable using traditional methods. For many, it was more than 50%. In addition, using the Forecast Value Added (FVA) methodology, many were degrading the forecast output.

Most companies have spent millions of dollars on planning systems, train and manage tens and hundreds of demand planners, and spend endless hours in meetings without asking basic questions. The focus is on item level forecasting at a ship-from forecasting level without consideration of:

- What does good look like? Am I improving the output?

- Are my products forecastable?

- How are products changing over time?

- What is the impact of the market on demand? Latency and bullwhip distortion?

- Is the order a valid signal to model?

Consider the homework results of one company in Figure 1. When I met this company, they measured Weighted MAPE at a three-month lag. They felt good about their forecast performance. The team wanted to buy a system. I shook my head. The business leader said not so fast. (Thankfully)

I asked the company to map their demand streams. Note in Figure 1 that the very forecastable items have high customer service levels but represent only 7% of items and 7% of volume. In contrast, the items that are not forecastable represent 53% of items and 48% of sales volume. Customer service levels for these items (fill rate) are low. A traditional approach would stuff all of these items through a standard model without delineating or characterizing streams.

Figure 1. Forecastability, Volume, and Customer Service for a Manufacturing Company.

So What?

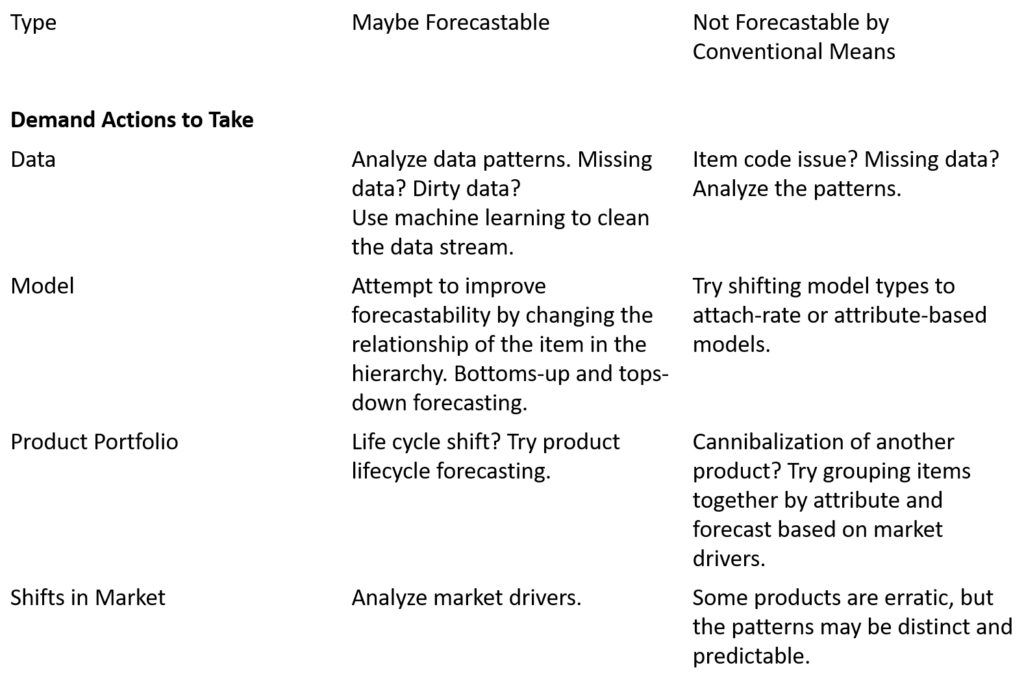

You might say, “Fascinating Lora, but so what?” The adaptive engine does not just match demand and supply. Instead, the new approach aims to align the insight to action. By recognizing the pattern, companies can adjust demand and supply strategies. This is a use case for generative AI.

Here are some use cases.

Table 1. Demand Strategies

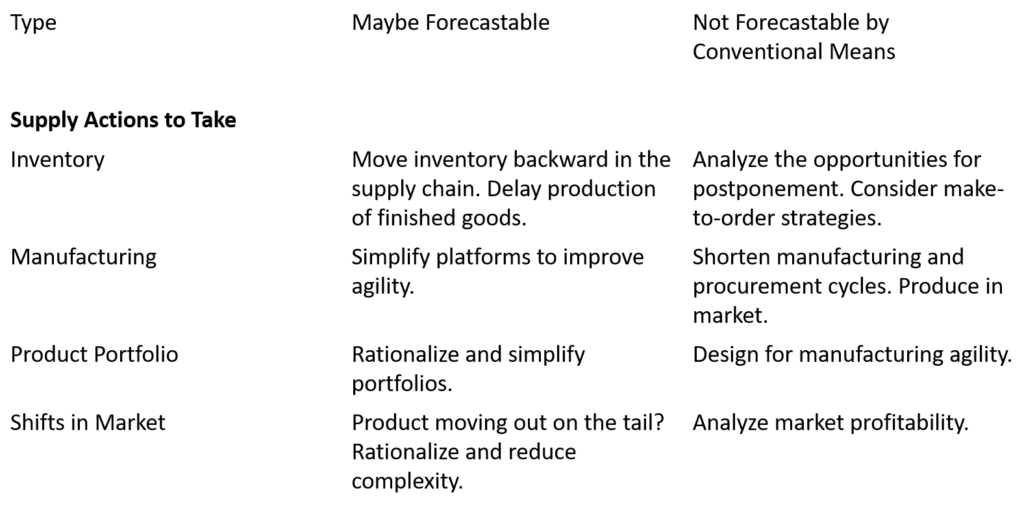

Contrast the Demand Strategies with Adaptive Supply Strategies in Table 2.

Table 2. Supply Strategies

Summary

I hope the example helps. Once you start analyzing demand streams, you cannot stop. When you see them, you cannot unsee the impact.