I smile every day. And, then scratch my head.

It seems that the term AI is everywhere, but nowhere. What do I mean? Conferences presentations, marketing materials, and blog posts drip with the term AI. The term is in vogue as panelists waft eloquently about the potential of AI. My LinkedIn feed bleeds AI.

However, the real use of AI (artificial intelligence) for the supply chain is still in its infancy. I think we are in the hype cycle of insanity. I am waiting for the curtain to rise for reasonable people to have a meaningful discussion. This is the goal of this post.

If we do not, we will have discussions on historic practices using better statistics and OR methods, while the pace of AI evolution offers great and great opportunities.

Reflection

When I speak of Artificial Intelligence, my definition is the combination of Large Language Models (the adoption of public and private generative AI), improving engines to improve insights (deep learning, pattern recognition, reinforcement learning, and machine learning), and agentic AI. (I share some definitions at the end of the post.)

Let’s start with the contrast of statistical models/ operations research (OR) and machine learning. The focus of OR engines is to yields an optimal solution for problems that can be modeled with a definite structure. In contrast, machine learning yields predictions from data that you cannot model perfectly. Most supply chain decisions need both. However, most of today’s traditional solutions lean heavily on OR trying in many cases to predict the unpredictable.

I label the automation of current planning processes as AI STUPID. The reasons? I base these five on observations from teaching over 350 students in outside-planning classes over the past four years.

- Process Gaps. I think that our current planning processes are badly broken. They are functional, linear, and backward looking. I liken the automation of current planning processes to telling Henry Ford that he needs faster horses. Riduculous right? Yet, most technologists want to lecture on how to build better engines — probabilistic optimization, deep learning on a graph database, or DDMRP– not the redefinition of work to improve value.

- Lack of Alignment of Responsibilities and Accountability. Today’s processes are dependent on planners. One of the problems in this work definition is that planners are responsible, but not accountable for their decisions.

- Less is Known. Traditional planning approaches assume a known cause and effect. What I find in teaching the outside-in classes is that fewer decisions are made in the area of a known cause and effect. (The premise of traditional Advanced Planning Solutions (APS) was that there was a known cause and effect relationship.) Known/unknowns include new product launch, disease, product cannibalization, entry into new regions, or the translation of tarriff costs to consumer behavior. Unknown/knowns include earthquakes, hurricanes, droughts, rate of platform adoption, or the cadence of product lifecycles.

- Value Delivery. Most supply chain processes that I analyze are generating waste not creating value. It is not the intention, but it happens because companies are not aligned on measurement and the definition of a good plan. In most companies, I find a negative Forecast Value Added value (FVA) translating to unneeded inventory and bullwhip amplification. The bullwhip varies from a factor of 2-9 depending on the industry. As a result, most S&OP processes increase process latency without adding value. In my outside-in planning course, less than 10% of the participants over the past four years measure FVA. Most focus on error reduction (Weighted MAPE is the worst.) not on the delivery of value. Few measure forecastability. If an item is not forecastable, why forecast it?

- Multiplicity of Constraints. The original definition of APS focused on manufacturing as a constraint, but today, companies need to trade off multiple constraints from make, source and deliver together.

So, please don’t call me to discuss the addition of agentic AI to existing planning technologies. I really don’t want to call you STUPID. If you are pursuing autonomous planning of existing planning systems through AI, please STOP. If you are a smart mathematician with a better mousetrap, please focus on how better math in combination with the evolution of AI techniques can improve decisions holistically.

Observations from Outside-in Planning

Today, I wrapped up the fall classes on building outside-in planning processes. My goal is to build a guiding coalition for change. So that we stop having discussions about AI Stupid and drive meaningful change.

Over the last four years, 350 business and technology leaders took the classes, and we are continuing the discussions in a monthly share group. (The materials used in the class will be in Ask Lora in February using agentics on top of a large language model which will allow companies to query the data and build their own plans. )

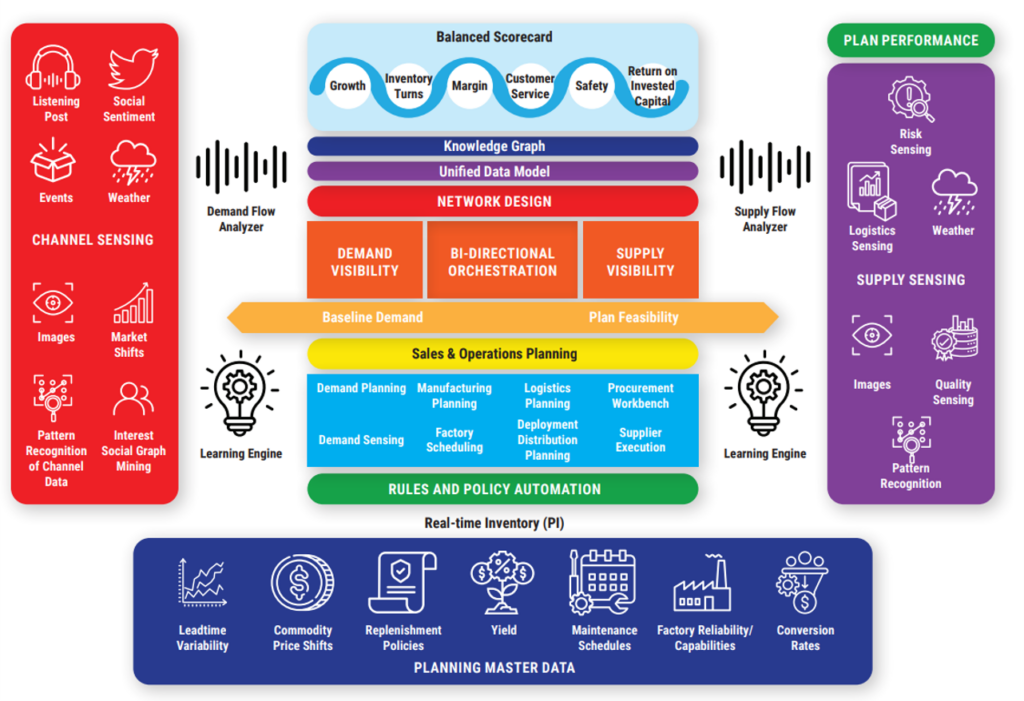

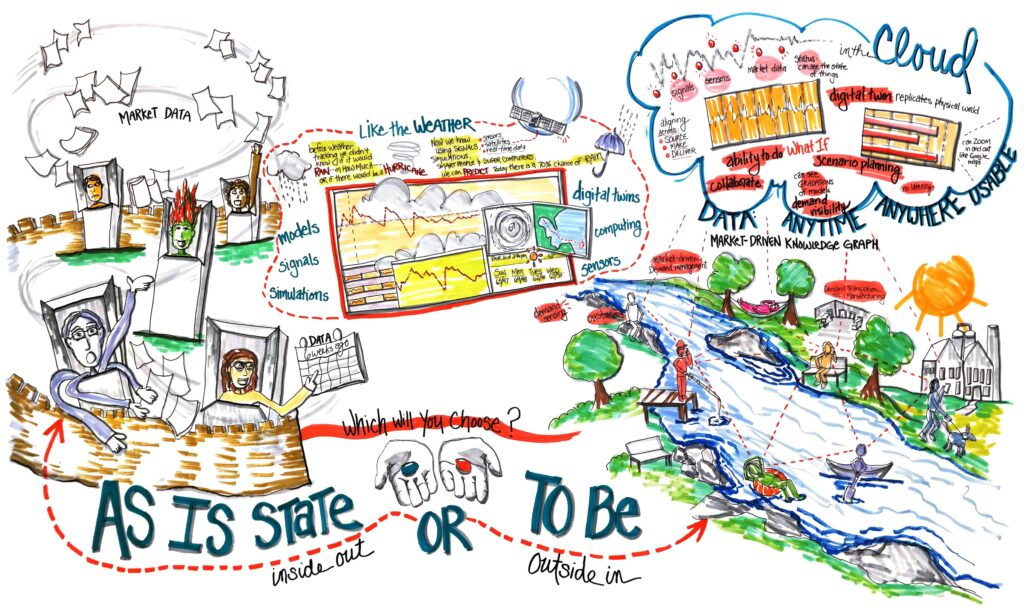

I am excited that we are starting to see the evolution of technologies that can model outside-in planning. Up until this point, companies wanting to implement outside-in planning were forced to do a custom build by data scientists. Today, the native AI platforms enable a unified data model while build insights on a knowledge graph to optimize make, source, and deliver trade-offs and buffers at the same cadence as S&OP. In addition, the use of machine learning and pattern recognition using schema on read techniques enables continuous learning of planning parameters.

In today’s class, we discussed the use digital twin assistant(s) (think about personalized digital twins) for business leaders up and down the river of demand. We also discussed the use of Large Language models to understand the reasons and root causes for order shortages, returns, and schedule adherence issues. Generative AI in combination with discrete event simulation is an opportunity for training.

Supply Chain Insights Taxonomy of Outside-in Planning

So, why are outside-in planning processes important? Outside-in processes shorten the time to know. For an apparel retailer, in the class, decision insights could be 30-days quicker while a pharma company gained insights 60-to-90 days earlier.

To make the transition, companies need to learn from the past to unlearn traditional supply chain definitions. For many–with egos rooted in traditional thinking–this can be mighty uncomfortable. At the beginning of each class, I ask each student to start an unlearning journal. This is not as simple as change management.

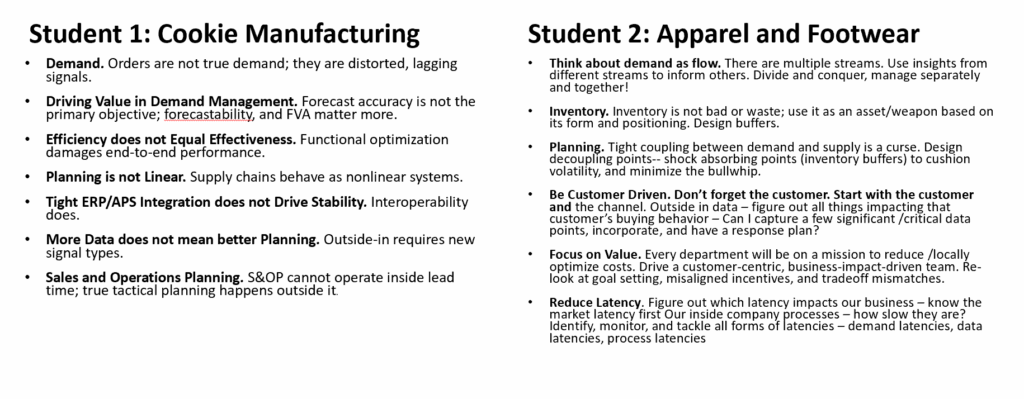

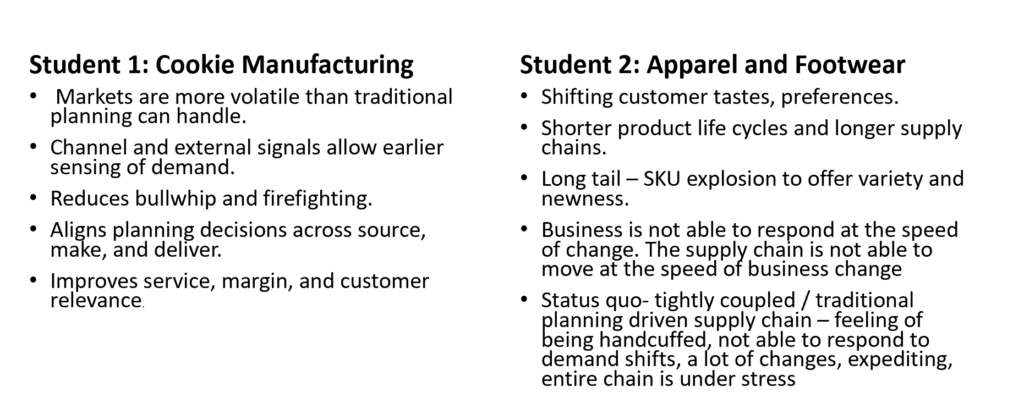

Here are the unlearnings from two companies that took the class during this period:

When I asked the companies to list why outside-in processes matter to them in the final homework, the answers for the two industries were similar:

For example, in the development of S&OP as the number of unknowns increase, the S&OP process is built with insights from playbooks. There are many playbooks developed based on likely scenarios. The playbooks are then consumed in the operational and executional horizons.

This process is analogous to the development of spaghetti models for hurricanes. In the beginning, when hurricanes are forming off shore, many models are identified using the best data possible. However, based on the number of unknowns, predicting one path impossible. As more data is known, the models are consumed. Outside-in S&OP is analogus.

Summary

The evolution of technology is a great enabler for supply chain leaders to drive value in planning. However, the greatest value happens when we focus on the redefinition of work based on market insights. The automation of existing planning processes is inadequate; yet, this is where I see most companies focusing.

A Favor

So, how do we evolve to outside-in processes while redefining our relationship with data, coding, and models? How do we redefine work?

The answer is evolving, but it starts with a clear vision of what is possible. To do this, we need to step away from the current definitions of work and redefine organizational workflows holistically. Role redefinition –a demand planner, a supply planner, procurement buyer, manufacturing planner, S&OP planning–should not be redefined in isolation. Instead, it requires the redefinition of work for all planners together and for the planning process holistically.

If you are reading this research, I would love your help to participate in research on the redefinition of supply chain platforms. My goal is to give to you through my writings when you give to me by filling out research studies. My business model is base on I give to you and you give to me. I will share the results of the survey openly here on this blog and through future reports/training. Click the link to share your insights.

Let’s learn together! The AI survey is open to all–business users, technologists, and consultants while the warehouse management cost to serve survey is limited to those business leaders in manufacturing, retail or 3PLs familiar with warehouse operations. Unfortunately, our processes don’t start with the customer. Managing cost-to-serve helps companies to stay competitive with the changes in product mix. The survey link for the warehouse management cost-to-serve survey: Cost-to-Serve Survey .

All respondent data will be shared confidentially without attribution.

If you can complete the surveys, a big thanks!

Definitions

Agentic AI: The use of artificial intelligence systems to operate autonomously, making decisions and performing tasks with minimal or no human intervention. The processes focus on solving complex goals and adapt based on data inputs, often utilizing techniques like machine learning and natural language processing.

Agents: In agentic AI are autonomous software programs designed to perform specific tasks and make decisions with minimal human intervention. The agents work together in a coordinated manner to achieve complex goals, adapting and learning from their environment in real-time. Agent governance is paramount to drive outcomes.

AI. There are many forms, including Large language models, reinforcement learning, deep learning, and agentic AI. The pace of development is happening quickly and will continue to evolve.

RAG. Retrieval-Augmented Generation. A coding technique that enables large language models to retrieve and incorporate new information. With RAG, LLMs do not respond to user queries until they are prompted to refer to a specified set of documents allowing LLMs to use domain-specific and/or updated information that is not available in the training data

MCP – Model Context Protocol. I think of MCP like a USB-C port for AI applications. Just as USB-C provides a standardized way to connect electronic devices, MCP provides a standardized way to connect AI systems to external inputs.

Python. An established itself as the go-to programming language for Artificial Intelligence (AI) and machine learning. Its simplicity, flexibility, and vast ecosystem of libraries make it indispensable for both beginners and experienced AI practitioners.

Semantic Reconciliation involves resolving differences in data meaning, terminology, and structure. This process typically includes schema matching, ontology alignment, and semantic mapping.