It is finally spring in Philadelphia. Yesterday, as I walked the streets on the way to ballet, I saw flowers for the first time in a year. I love spring. It is a time for awakening.

My body is decompressing from travel, but my mind is full of ideas. I have been on the road for the past three weeks speaking at seven events. Travel is both enriching and exhausting. As I walked, I reflected on the many discussions that I have recently had with multiple supply chain leaders on Supply Chain Excellence. Ahead, I have a week of writing. I am busy finalizing a report on the current state of the inventory optimization market, rewriting and updating a report on Sales and Operations technologies, and penning a new report on Supply Chain Centers of Excellence. (We are also finishing up quantitative studies on inventory optimization and Sales and Operations Planning. We would love your input.)

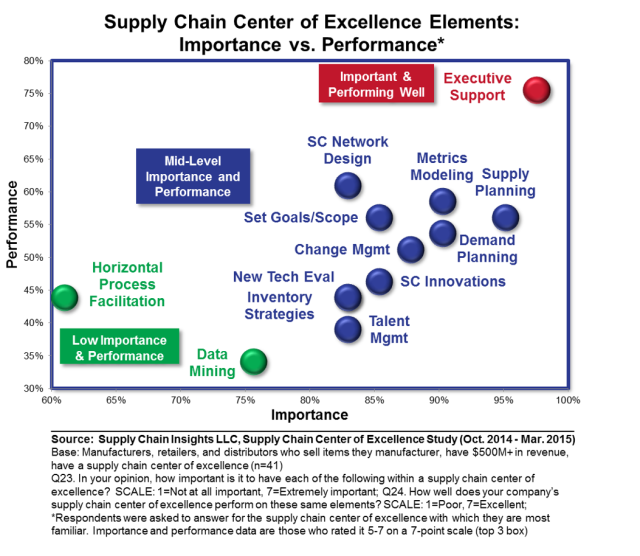

Today, I am deep into the recent research on the Supply Chain Centers of Excellence. We have pulled the data from the field on the Supply Chain Centers of Excellence survey; and to gain insights to finalize my thoughts for the report, I am sharing the data with two groups of supply chain leaders: those that have a center of excellence, and those that do not. Last week I spoke to 26 attendees that had a center of excellence; and this week I will speak to 15 companies that do not have a center of excellence, but are considering the implementation of the concept. I am sharing charts like those in Figure 1.

Figure 1. Center of Excellence Elements

What am I finding?

1) Origin. Most supply chain centers of excellence evolved from a multi-year ERP implementation, or the evolution of a strategy to form a global multinational supply chain.

2) Charter. For most companies, there is confusion on the charter. While the evolution of supply chain excellence is forward-looking and visionary, most have defined the center to focus on expertise or competency. The difference is the assumption that there are ‘supply chain best practices’. The difference? A center of expertise works on the standardization of best practices, while a center of excellence focuses on the improvement of performance. In this world of supply chain practice, where processes are only 30-years old and still evolving, this is a very big difference.

3) Maturity. As shown in Figure 1, the processes are the most mature in the areas of network design. There is also intense focus on the implementation of demand and supply planning. However, the areas of talent development, inventory management, and the implementation of horizontal processes (Sales and Operations Planning, Supplier Development and Corporate Social Responsibility) are less mature.

4) Regional Global Governance. Most centers of excellence struggle with the issues of global governance. To be successful, it is important to answer the question of, “What is the role of the corporate planning team, and what is the role of the region?” Many learn this too late. Answering this early and often is essential to survival in a sea of corporate politics.

5) Supply Chain Excellence Work Is Important. For companies that have a mature Center of Excellence working on horizontal processes and talent development, there is greater alignment and organizational agility. A focus on excellence is quite different than a focus on expertise. I am trying to understand the drivers through my interviews with the leaders. So to get the full scoop look for the report….

If you and your team are interested in learning more, you will not want to miss the Supply Chain Insights Global Summit. Designed for supply chain visionaries, the conference is limited to 150 supply chain leaders. Held at the beautiful Phoenician Hotel in Scottsdale, AZ. on September 9th and 10th, it is an ideal place for leaders and visionaries to connect. Join us for the event which focuses on seven important themes:

- Supply Chains to Admire: At this conference we will unveil the results of the second year of analyzing supply chain improvement and performance by industry in our work on Supply Chains to Admire. Understand what is possible as you listen to the stories of these supply chain leaders.

- Race for Supply Chain 2020: Two leading economists—Dr. Richard Florida and Dr. Pankaj Ghemawat—will share insights on the future of world trade and the changing nature of world demographics. The world is not flat and there is more friction across borders than there was prior to the great recession. Learn what the future will hold and how to best prepare.

- Power Growth through New Technologies. Mobile. Augmented Reality. Corporate Social Responsibility. Collaborative Economy. 3D Printing. Cognitive Learning. Robotics. There is a flood of new technologies and approaches to change traditional supply chain models. Join the afternoon of September 9th to understand how companies like Jabil, Green Eileen, and Sidecar are using these new technologies to power growth.

- Digital Supply Chain. Gain an understanding of what is a digital supply chain, and learn more about the capabilities of new technologies to drive innovation. Join the digital showcase on the first day to get hands-on experience and gain exposure to case studies by supply chain leaders that are driving outside-in transformations.

- Supply Chain Transformation: Join the morning of September 10th to gain insights on supply chain transformation case studies. This session will end with a panel discussion of leading experts sharing insights on building demand-driven processes, and companies like Colgate, Land O’ Lakes and Procter and Gamble will share insights from the Supply Chain Insights planning benchmarking work.

- Power of Outside-in Processes: If you have played the beer game, and are looking for a new way to help teams understand the complexities of supply chain management, we have designed the afternoon of September 10th for you. Spend the afternoon enjoying and playing the new simulation game built by Sterling Simulation and Supply Chain Insights to demonstrate the power of outside-in processes. Network with your peers on the insights and relax under the Arizona skies as you wrap up a couple of intense days.

- Network with Leaders. This is the place where supply chain innovators talk to supply chain visionaries. It is unlike any other conference. If you are looking to stretch your thinking, put this conference on your agenda.

We hope to see you there!

_______________________________________________________________

Lora Cecere is the Founder of Supply Chain Insights. She is trying to redefine the industry analyst model to make it friendlier and more useful for supply chain leaders. Lora has written the books Supply Chain Metrics That Matter and Bricks Matter, and is currently working on her third book, Leadership Matters. She also actively blogs on her Supply Chain Insights website, at the Supply Chain Shaman blog, and for Forbes. When not writing or running her company, Lora is training for a triathlon, taking classes for her DBA degree in research, quilting for her new granddaughter, and actively taking ballet.