I pushed aside Shane’s motorbike helmet and jacket to take a seat in his crowded office. It was a beautiful spring day in March in Basel, Switzerland. Shane is a stocky man of medium build who I love talking to. He is an engaging personality: definitely a people person.

He had recently returned from his stint as the commercial leader for Syngenta in Vietnam, and was excited to tell me about his beach-side investment in Australia. An Aussie by birth, Shane still speaks with an Australian accent.

![]()

Syngenta AG is a global Swiss agribusiness that markets seeds and agrochemicals. The company’s focus is on biotechnology and genomic research. The company formed in 2000 by the merger of Novartis Agribusiness and Zeneca Agrochemicals.

Shane’s Story

I first met Shane in 2007 at the beginning of his work with Syngenta’s value chain. At that time, his team was actively building a demand-driven strategy. I was working at AMR Research, and the group asked for help to understand the concepts of being demand-driven . It had been a whirlwind trip across Europe, and I was tired. I don’t remember what I said, but I do remember Shane. As I stood up to give my standard speech, Shane engaged me in dialogue. I loved his style and charisma with the team. It sparked a great debate.

I was excited to return on this windy, spring day to talk to Shane—seven years later—to ask him for reflections. Seldom do I see a commercial leader transition to supply chain, and I wanted to gain his insights.

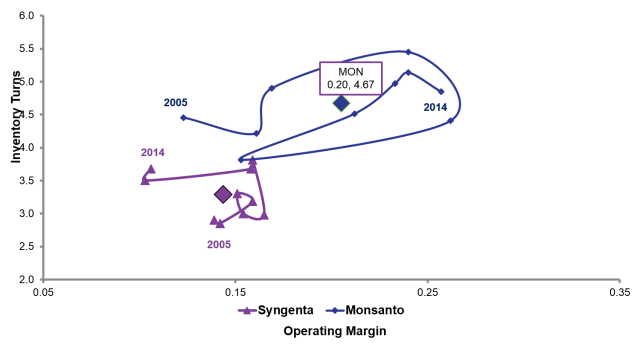

Figure 1. Orbit Chart Comparing Syngenta and Monsanto Progress on the Effective Frontier –

Balancing Inventory Turns and Operating Margin for the Period of 2005-2014

In 2007, Shane Emms was asked to take a Global Supply Chain leadership assignment at Syngenta. With a career in marketing, and very little understanding of supply chain, he was afraid that his new team would ask, “What does this guy know?” However, in 2008 when the business grew +20%, inventories declined substantially, and part of his team won a Syngenta internal award, it became clear. While Shane did not start out with a supply chain background, he was a fast learner and a great leader. (Use the orbit chart in Figure 1 to follow Shane’s progress through the recession. He led the team during the period of 2007-2009. Note the improvement and the resiliency in supply chain performance.)

When I asked Shane, during my recent trip to Basel, Switzerland, to tell me how he orchestrated the transition, he replied, “There were two immediate actions. I pushed hard to get the supply chain team to understand the commercial challenge; and I also worked diligently to give the supply chain team an identity, and I then asked them to stand up to that identity.”

He smiled and laughingly said, “Supply chain guys are serious and smart folks, but don’t always know how to market their work. They are great problem solvers, but sometimes they do not understand the elements of the commercial enterprise.” The Syngenta team, under Shane’s leadership, built their identity around the slogan of ‘Deliver today, design for tomorrow’.

Shane continued, “We lived this identity and promoted it within the company. It was important: the lines were being drawn between commercial and operations teams, and we had to focus to help the two groups work better together—we were the most important link of the supply chain.”

“It seems like yesterday because it is so vivid in my mind. The times were tough. In 2008 the market was ballistic. Commodity prices were driving high interest in agriculture and we had run out of a lot of product. To focus, we identified about 23 areas that we could tweak to improve the responsiveness of supply. We were out of capacity, needed to build it, and needed to redefine the supply chain. My goal was to ensure that each person on the team felt like they had a stake in the business and the opportunity. We focused on how to work with the commercial teams. Initially, it was in two areas.” Shane said.

He then described this work. “My first goal was to get the supply chain team and commercial teams working together, not one way. When it came to working with the commercial teams, I asked each person on the supply chain team, where appropriate, to consider saying ‘No’, and mean it, and stick to their guns.” With a twinkle in his eye, Shane said, “Getting along often means standing up in an astute way for the company’s benefit, not any one function over another.”

He cleared his throat and continued, “My next focus was on building stronger business partnerships. I asked the team to get involved with the business. I think all supply chain leaders need to know where the money comes from, and customer’s needs. So, I encouraged them to pull up their chairs with the commercial teams, and get involved, and better understand the business and continue to seek where we can create and add value.”

” You know that our supply chain is complex. We outsource about 80% of the primary ingredients of our crop protection business, and pack it in finishing plants and ship to warehouses. The front-end of the supply chain performs very differently than the back-end,” he said as he rose from his seat to write on his whiteboard. With a black marker, he drew a series of boxes that represented the Syngenta supply chain. The emphasis was on making active ingredients and pushing them to a decoupling point to push finished products to market. He continued, “We needed to be responsive to the market. By doing this, our sales teams got an extra leg up on the competitors and drove sales, while we could bring working capital down.”

My Take

To understand supply chain excellence, and the impact of a leader, you need to compare the results of peers. In Figure 1, I share the orbit chart on the pattern of inventory turns and operating margin for two competitors: Monsanto and Syngenta. The potential of the Syngenta and Monsanto businesses is very different. Like most market leaders, it is based on product portfolios and market strategies. The goal of a supply chain leader is to maximize the potential. As can be seen in Figure 1, Monsanto outperforms Syngenta. However, take a closer look at the Syngenta and Monsanto patterns through the recession when Shane was leading the team. Note the resiliency in Syngenta’s supply chain and the small incremental improvement under Shane’s leadership. While Monsanto has a higher overall performance, the Monsanto team lost control of the supply chain in the rebound from the recession.

Shane’s work on commercial and supply chain team alignment improved resiliency. The alignment between the commercial and operational teams is both difficult and important. This is why I think this is an important story.

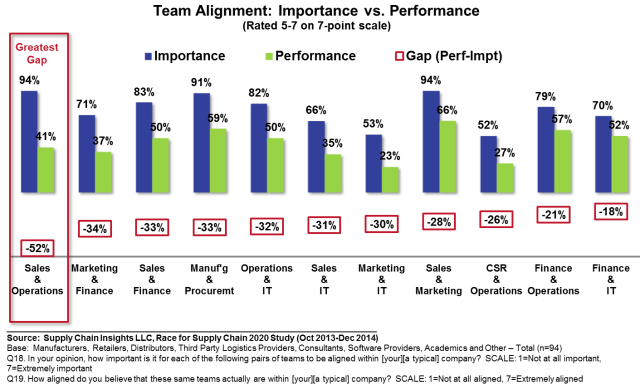

In our research two years ago on supply chain alignment, as shown in Figure 2, the lack of alignment in most supply chains is a gap, and I agree with Shane… a missing link in most supply chains today.

Figure 2. Organizational Alignment: Closing the Critical Link Between Sales and Operations

Congrats to Shane and to the team for closing this gap. It was important in building resiliency and driving improvement in the Syngenta supply chain. What do you think? I would love to hear your story. Write and let me know how you and your team have tackled alignment and built strong relationships with the commercial teams. I know of very few of these stories, and I think that they are important.

To hear more stories like Shane’s be sure to mark your calendar to attend the Supply Chain Insights Global Summit. We are finalizing the agenda and would love to see you there:

Meet Baxter and Sawyer. They are attending the Supply Chain Insights Global Summit, and they’re hoping you are too! They will be featured in our digital showcase and are a part of the Jabil story on digital manufacturing. We are busy putting the final touches on the agenda to help you Imagine the Supply Chain of the Future. In this year’s agenda, we are featuring some great case studies on new business models—Green Eileen and Sidecar—that I think that you will enjoy.

This is my third year of hosting the annual Supply Chain Insights Global Summit. I hold the event at The Phoenician in Scottsdale, AZ on September 9-10. It is an exclusive group of 150 supply chain leaders and is limited to 15% technology providers.

We are finalizing the agenda this week against seven exciting themes:

- Supply Chains to Admire. At this conference, we will unveil the results of our second study on supply chain performance and improvement. In this session, you will gain an understanding of which companies have driven the fastest improvement and highest level of performance. Understand what is possible as you listen to stories of these supply chain leaders.

- Race for Supply Chain 2020. Two leading economists—Richard Florida and Pankaj Ghemawat—will share insights on the future of world trade and the changing nature of world demographics. The world is not flat and there is more friction across borders than there was prior to the great recession. Learn what the future will hold and how to best prepare.

- Power Growth through New Technologies. Mobile. Augmented Reality. Corporate Social Responsibility. The Collaborative Economy. 3D Printing. Cognitive Learning. Robotics. There is a flood of new technologies and approaches to change traditional supply chain models. Join us the afternoon of September 9th, to understand how companies like Jabil, Green Eileen, and Sidecar are using these new technologies to power growth.

- Digital Supply Chain. Gain an understanding of what is a digital supply chain, and learn more about the capabilities of new technologies to drive innovation. Join us at the digital showcase during our Welcome Reception on September 8th to get hands-on experience and gain exposure to case studies by supply chain leaders that are driving outside-in transformations.

- Supply Chain Transformation. Join us the morning of September 10th to gain insights on how Lenovo, Wright Medical and Seagate have driven supply chain transformation. This session will end with a panel discussion of leading experts sharing insights on building demand-driven processes as participants share their insights from the Supply Chain Insights planning benchmarking work.

- Power of Outside-in Processes. If you have played the beer game, and are looking for a new way to help teams understand the complexities of supply chain management, we have designed the afternoon of September 10th for you. Spend the afternoon enjoying playing the new simulation game built by Sterling Simulation and Supply Chain Insights to demonstrate the power of outside-in processes. Network with your peers on the insights and relax under the Arizona skies as you wrap up a couple of intense days with your peers at the final reception.

- Network with Leaders. This is the event where supply chain innovators talk to supply chain visionaries. It is unlike any other conference. If you are looking to stretch your thinking, you will want to put this conference on your calendar.

Registration for the event is now available, and there is a special discounted room rate at The Phoenician if you register early. See you there?

All the best on your journey for supply chain excellence. Thanks for reading the Supply Chain Shaman blog, and thanks to Shane for sharing his story. I hope to see you at the Supply Chain Insights Global Summit…

_______________________________________________________________

Lora Cecere is the Founder of Supply Chain Insights. She is trying to redefine the industry analyst model to make it friendlier and more useful for supply chain leaders. Lora has written the books Supply Chain Metrics That Matter and Bricks Matter, and is currently working on her third book, Leadership Matters. She also actively blogs on her Supply Chain Insights website, at the Supply Chain Shaman blog, and for Forbes. When not writing or running her company, Lora is training for a triathlon, taking classes for her DBA degree in research, knitting and quilting for her new granddaughter, and doing tendu (s) and Dégagé (s) to dome her feet for pointe work at the ballet barre. Lora thinks that we are never too old to learn or to push for excellence.

______________________________________________________________