Last week was the sixth anniversary of my founding of Supply Chain Insights. Over 1000 people wrote me congratulatory notes on LinkedIn. Most were from people who I do not know. I find this rewarding and humbling.

Last week was the sixth anniversary of my founding of Supply Chain Insights. Over 1000 people wrote me congratulatory notes on LinkedIn. Most were from people who I do not know. I find this rewarding and humbling.

February also marks my eighth year of blogging. The journey of creating Open Content research and blogging is a life journey that chose me. I didn’t choose it. The path is one that I could not have predicted. When I was in college, the concept just did not exist. The idea of sitting at my kitchen table and reaching 1000s of supply chain leaders was unthinkable.

When I worked for AMR Research, I believed I would work there until I retired. I could not have predicted the founder of AMR Research selling the company to Gartner Group. With his sale to Gartner, I had to leave. I do not believe in the Gartner model. The reasons why I don’t believe in the Gartner model are a subject for a late night drink at a bar. In essence, my goal is to be independent and be able to write on the evolution of the world of technology as I see it unencumbered by pressure from large technology firms. I just do not believe in pay-to-play. I wanted freedom to write as I see the world.

When I started, I had no idea of the power of Open Content research. To frame the discussion, let me share some reference data. When I worked in traditional research companies (Gartner and AMR Research)–with the research tucked-up behind paywalls–1800 business leaders read my articles on a good day. In contrast, today, my articles on LinkedIn reach over 250,000 global readers, and this blog has 1800 readers on the direct RSS feed, and 15,000 supply chain leaders around the world read the content. Each day, I get inquiries to put advertising on this blog. I turn them down because I am fiercely independent. The digital evolution made my building of Supply Chain Insights, and the new business model, possible. However, I would not have done it if AMR Research was not bought by Gartner. Digital business models usually happen either out of failure, desperation, or the result of a visionary leader.

When it is time for a baby bird to fly, the mother pushes the bird out of the nest. I think the adoption of digital processes is analogous. I would not have started a new business model unless I was forced to fly on my own. I see it everyday in discussions with business leaders.

Reflections

I think this is a good context for a discussion today, in this blog, on the digital supply chain. Last week, I had discussions with digital supply chain leaders from three companies. The conversations were similar, “How can I get my business leaders to embrace a digital transformation journey?” In essence, today manufacturing leaders are flooded by presentations from consultants attempting to sell a message to begin a digital journey. The reason? It is a new gig. ERP projects are drying up and the consultants need to create their new market. We are in a hype cycle.

On the calls, we discussed the difference between the digitization of data and the creation of digital processes. At the end of one of these discussions, the person on the other end of the Skype call said, “I work for a German company. There is no reason to change. In the German language, there is no distinction between the terms digitalization and digitization.” In the conversation, we laughed and postulated that this might be a reason why German software companies are so slow to redefine the Art of the Possible.

What Is Digital?

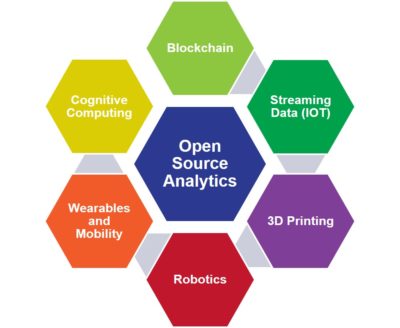

Figure 1. Technology Drivers

I define the digital supply chain as rethinking the atoms and electrons of the supply chain to drive new levels of value. For example, do we need orders with the evolution of blockchain as the system of record? With additive manufacturing, do we need inventory? With software robots and rules-based ontologies, can we redefine a more effective and autonomous process for customer service? With Amazon owning 40 planes and 300 warehouses do we need traditional 3PLs? Can a retailer print products in their store? Or a hospital use additive manufacturing to produce/print organs for transplant? The answer is yes. The question is when. The shift takes courage, leadership and vision.

The concept of the integrated supply chain is becoming outdated as companies look at building architectures that can sense, translate, think, and act. “Schema-on-read” architectures are replacing “schema-on-write” technologies like Enterprise Resource Planning (ERP) and Advanced Planning (APS) in the areas of visibility, track, and trace. Traditional schemas are too confining for decision support, visibility, and other functional applications. In our recent webinar on visibility, Merck discussed the use of a schema-on-read architecture augmented by cognitive computing as shown in Figure 2.

Figure 2. Merck’s Vision for Supply Chain Visibility

In an earlier webinar, we discussed how a major manufacturer is redefining proof of delivery (POD) using sensors, and streaming data, with open architectures from Kafka and Apache Spark. While laggards speak of expanding SAP HANA, innovators are pushing the use of open architectures like Hadoop and Blockchain.

In the process, manual coding of master data is becoming obsolete. Machine learning and rules-based ontologies are mapping the data automatically sourced from data lakes. Leaders are making small steps towards the building of an autonomous supply chain that can adapt. The givens are giving way to new possibilities.

Driving Change/Pushing Change

Why change? As we talked on the phone, what became clear is that while individuals want to drive change, and are provoked by consultants to rethink their supply chains, the challenge is just too tough. Taking the jump to define and drive digital supply chain thinking is a risk for the well-paid individual with great benefits. The entrepreneurial spirit is not alive and well within the large manufacturing company. The digital supply chain is just too big of a risk for the average employee. An organization is designed to drive improvement in the status quo, but does not encourage employees to rethink supply chain processes. While organizations are very focused on the development of new products, the same is not true for the redefinition of new processes. It requires leadership. Just as I was forced to create a new model, there needs to be a compelling event or push from leadership.

Showcasing this leadership is the goal of our September Global Summit. I handpick the case studies. (I have confirmed four case studies.) There are no sponsors. There will be no technologists on the stage. The conference focuses on helping business innovators do just that, innovate. Two people per company can attend, and we limit the attendance to 35 technologist/consultants. Last week, we sold out of seats for technology vendors, and we only have seats for 60 supply chain business leaders to attend. Sign up now to reserve a seat for you and your team. We hope to see you there! It is a time for you to think differently and make a difference.

Turn Off the Fog Machine: Move Past Groupthink to Drive A Positive, Data-Driven Narrative

In this blog post, Lora Cecere, Founder of Supply Chain Insights, asks if our current focus on doom and gloom is a fog machine, and a barrier to driving improvement.