Typing away on a beautiful May morning, with the flowers blooming and the birds nesting in the garden, engages my mind. Mondays are my day to post my Shaman blog and compose a podcast. The Shaman blog is now over eleven years old.

I remember my first post like it was yesterday. New then to WordPress, it took me a week to finish the post. (It was a struggle!) Now the writing follows the research. I mix the quantitative research with my observations and interviews, and the posts seem to roll from my fingers. I appreciate you as a reader and enjoy your comments. Over 28,000 readers read this blog. I give thanks.

My goal is for me to give to you and for you to give to the community. Let me explain, if you fill out one of my surveys on LinkedIn, I share the research results in front of the paywall (I believe that supply chain research should be readily available and not locked behind a paywall.) (If you would like to participate in a current research study, we would love your help and participation in the contract manufacturing study. We are trying to assess the value of a network in managing contract manufacturing.) When I use the research, I keep the information on the respondent–name, company, title, and individual comments–confidential. I only share the results in aggregate.

A Closer Look at Organizational Alignment

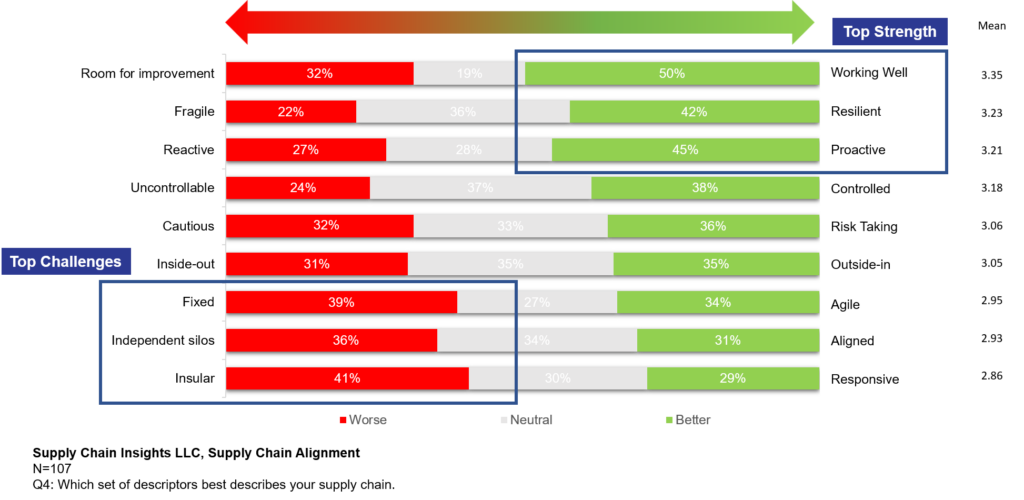

In a recent survey on organizational alignment, I asked the respondents to rate their supply chain based on counter-opposing adjectives. Note that the respondents in Figure 1, 50% see their supply chain as working well, 42% view it as resilient, and 45% see it as proactive, but only 31% feel that their supply chain is aligned. Most see their supply chain as fixed and insular.

Figure 1. Use of Supply Chain Descriptors

Most organizations are locked into functional silos driven by functional metrics. Stuck in a rut, supply chain leaders try to punch their way through a set of conflicting metrics and priorities each day. Functional excellence throws the supply chain out of balance decreasing results on a balanced scorecard of growth, margin, inventory turns, customer service and ROIC (Return on Invested Capital).

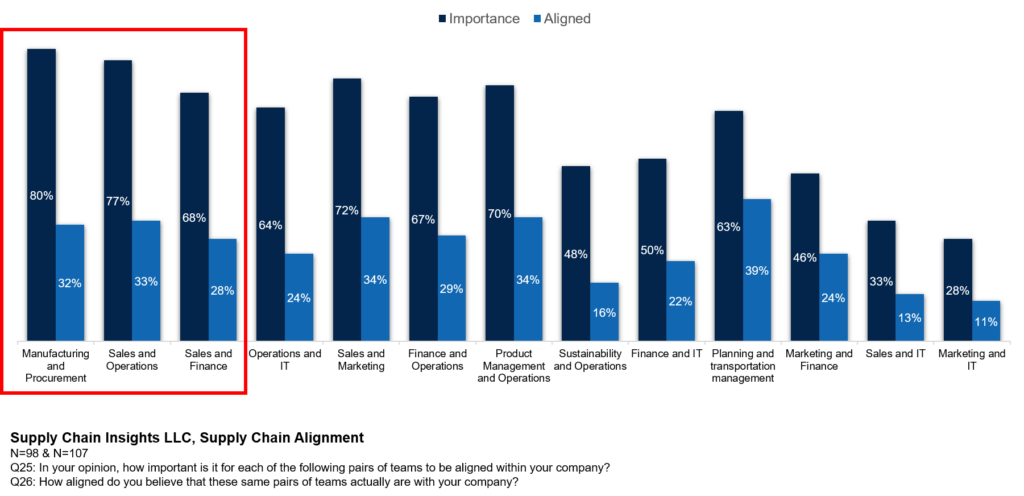

One of the alignment gaps that is growing and is unfortunate is the gap between procurement and manufacturing. This gap of 48% between manufacturing and procurement is the highest seen in studies across the decade. The metrics defining success in manufacturing and procurement do not align.

Figure 2. Current Organizational Alignment

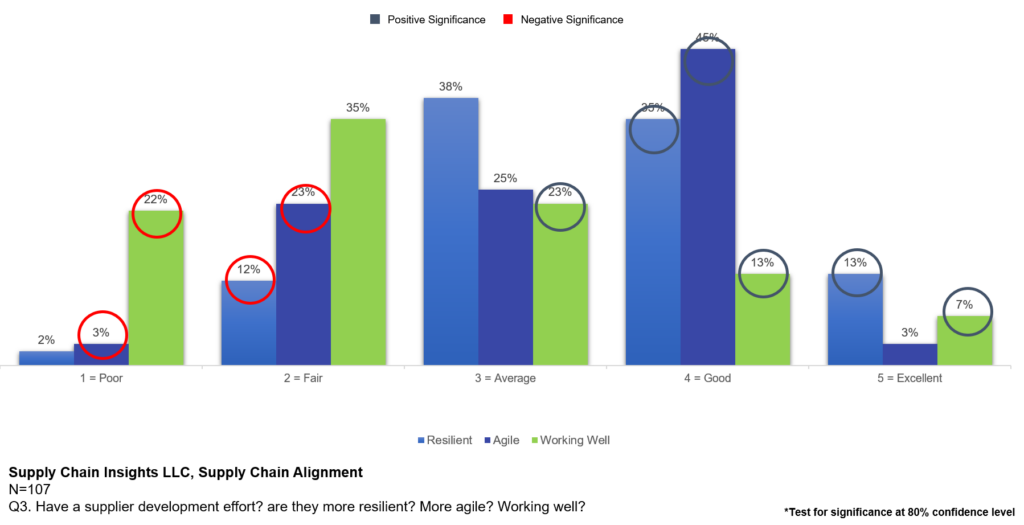

Figure 3. Impact of Supplier Development Programs on Organizational Descriptors

A Need for A Supply Chain Reset

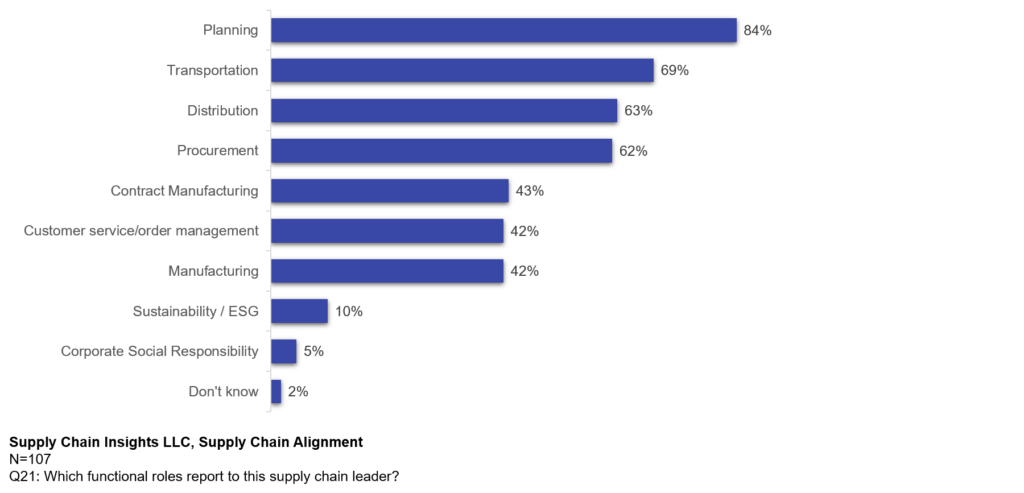

Most groups do not realize that they are out of balance. They operate daily within their ruts, not realizing that their views of excellence sub-optimize performance. Planners and customer service are caught between the alignment cracks trying to improve reliability in a dysfunctional organization.

Reset: An act or instance of setting again. an act or instance of setting, adjusting, or fixing something in a new or different way.

Merriam-Webster

If you have not checked it out, here is my latest report. In this report, I call for a supply chain reset: a need to redefine supply chain thinking. The goal is to improve the resilience of metrics performance in times of high demand and supply variability. For most, this requires the unlearning of traditional supply-centric concepts. The most critical element for organizations that rated themselves as “working well” during the pandemic phases was organizational alignment—hopefully a call to action for all.