Shifting sands. War. Tariffs. Shortages. Price increases. Ocean booking cancellations. Tightening of pocketbooks: changing demand patterns. Decline in consumer confidence. All are unsettling.

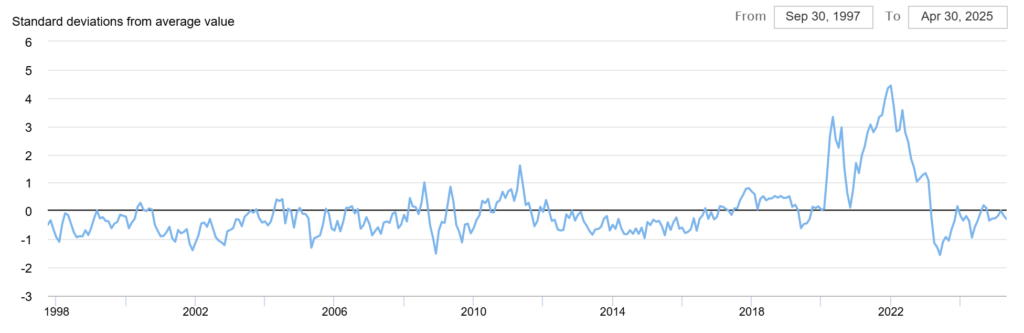

Companies are delaying hiring. Many are laying-off employees. The Global Pressure Index published monthly is rising, but we are still operating in a period of low variability. The larger uncertainty lies ahead.

Federal Reserve Bank of New York, Global Supply Chain Pressure Index, https://www.newyorkfed.org/research/policy/gscpi.

What can you do? Don’t just talk about variability. Measure it (both demand and supply) and use the insights.

Artificial intelligence (AI) is seen as the great enabler. But to enable what? Faster work as we know it? Shudder at the thought. Autonomous planning? A waste of time.

Employees are frightened. What does the change mean for their jobs? Careers? It is clear that the past is not a good model for the future.

The cycle of work is slowing as companies take a wait and see attitude for US commerce. The flow of goods to the United States is moving more now through Canada and Mexico to the United States, and the global multi-national is focused on growth programs where the business environment is more stable.

Focus on What You can Control

What to do? The first step is to girdle your anxiety. The second is to take charge of your career.

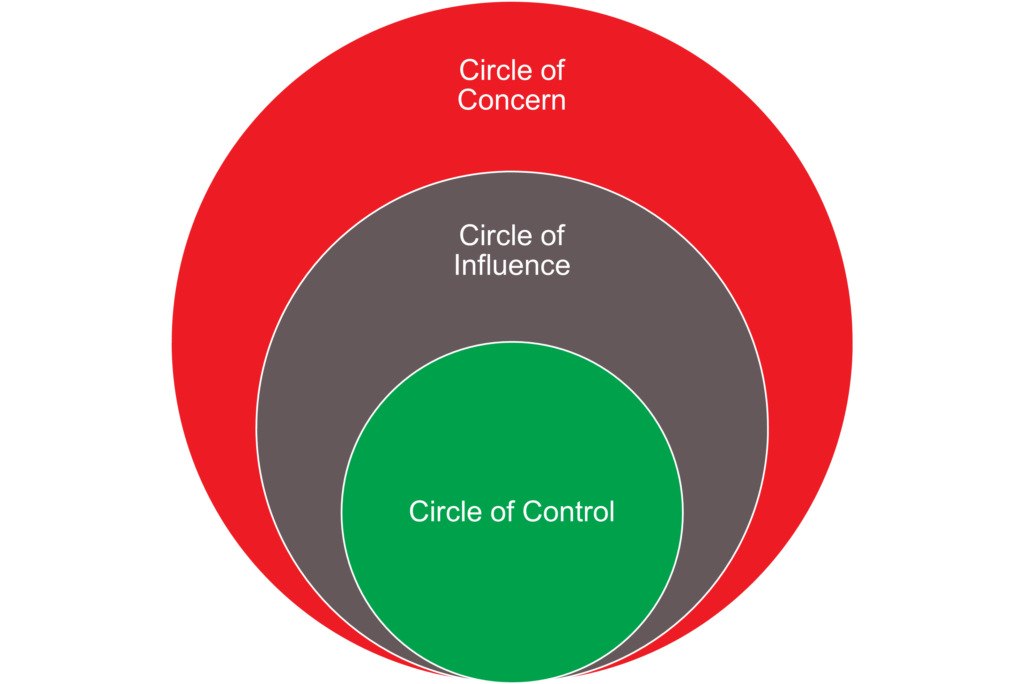

In every position, work to understand your circle of control. (These are the work processes that you are responsible for.) Focus here. Become an expert.

The second circle is your circle of influence. Work to build the circle of influence by networking, helping others, mentoring and volunteering for work assignments.

The third circle is your circle of concern. This circle is colored red for a reason. These are areas that you cannot control or influence. Accept what is in the circle of concern and make the best of it. Stay out of your circle of concern and widen your circle of influence.

For example, you cannot control governmental policy. You may not agree with the tax and tariff compliance mandates but face the fact that you cannot control it. Don’t waste time grumbling about it, just accept it for what it is.

Embrace the New Opportunity

I remember Evelyn and Rose, my secretaries, before the days of computers. At that time, there was no email. Memos were sent to typing pools to be distributed by inter-office mail. Every day, I got a notecard of meetings to attend. There were no schedules. We carried Daytimers. Interestingly, without computerization there was more face-to-face and ear-to-ear communication.

When computers were distributed to managers, Evelyn and Rose were scared. What would happen next? How would this affect their jobs? Would their jobs be eliminated? Both were very competent employees with associate degrees.

Evelyn took classes at night and became a Database Administrator while Rose reskilled to be a human resources administrator. Each saw the need to change and not dwell on the loss of the position as they knew it, but to embrace the potential of new opportunities stemming from the technology inflection. They were right. Their jobs were gradually eliminated. It happened faster than I predicted.

Today’s technology shifts are similar. If we accept processes as we know them, a struggle will ensue. But, if employees embrace the change as an opportunity, a win/win will emerge. Here are some thoughts.

- Planners to Orchestrators. The supply chain planning role has expanded over 100% as companies expanded their markets. I work with a company that had 210 planners in 2005 and now has 1475 global planners. And no one in the organization feels that the company does planning well. I agree with the assessment. In addition, the employees in this role, report the highest job dissatisfaction of anyone in supply chain. Let’s face it, the planning role as we know it is very inefficient. The process is slow and out of step with the market. Teams make recommendations based on latent data to their managers, but decisions are often bogged down in meetings and corporate politics. So, if you are a planner today, why not invest in learning how to become an Agentic AI Supervisor? In this role, you would design data flows to enable self-service planning processes where the planner becomes the orchestrator to help business leaders make the decisions at the speed of business. You would start by learning how to program AI agents. Critical to the learning is agent governance, the use of outside-in data, and clarity on what makes a good decision. No company should waste their time trying to make today’s planning processes more autonomous. The planning processes are broken by design because a planner is trying to drive a decision outside of their circle of control.

- Master Data Management Managers Move to Pattern Recognition Experts. The role of a master data management is going away. Data scientist techniques of pattern recognition, machine learning, deep learning and unstructured text mining, will automate a frustrating job that is neither rewarding nor ever finished.

- Expeditor to Product Flow Director. Today’s processes are reactive. Data arrives too late and often to the wrong person. In the evolution of technology, companies become better at sensing through multi-party networks and outside-in processes to build proactive workflows. The agents are constantly searching for gaps against plans and suggesting alternatives. The Product Flow Director is the orchestrator of outside-in data to feed agentic AI. With role-based workflow, the flow director can direct and guide the governance of the agents to deliver insights, drive bi-directional orchestration, and guide decisions at the speed of business to the organization.

You may not agree with me. I give these three scenarios as examples. Start your own journey.

We are at a tipping point. Be like Eveyln and Rose. Don’t waste your time at conferences playing buzz word bingo or immerse yourself in yesterday’s tech. Learn from the past to unlearn and rethink processes and define use cases for new tech within your organization.

Where to Start

Start with humility. Recognize that most supply chain leaders are structurally encased in their mental models with schema-on-write architectures. Don’t openly question the status quo.

Companies have invested in using transactional data, due to limitations in prior technologies. 80% of the data surrounding the supply chain is not used. The reason? The data does not fit neatly into rows and columns. Most of this data is unstructured –streaming data, text, images– and it does not easily fit into the simple if/then models of the relational database world. Start by making an appointment with your data science team and learn a new language and techniques. Become the business interpreter in the use of new forms of technology. Focus on how to use new forms of technology to solve supply chain problems in your circle of control.

Take classes on the use of Large Language models, Deep Learning, and Agentic AI. Network ferociously with others that are trying to take this journey.

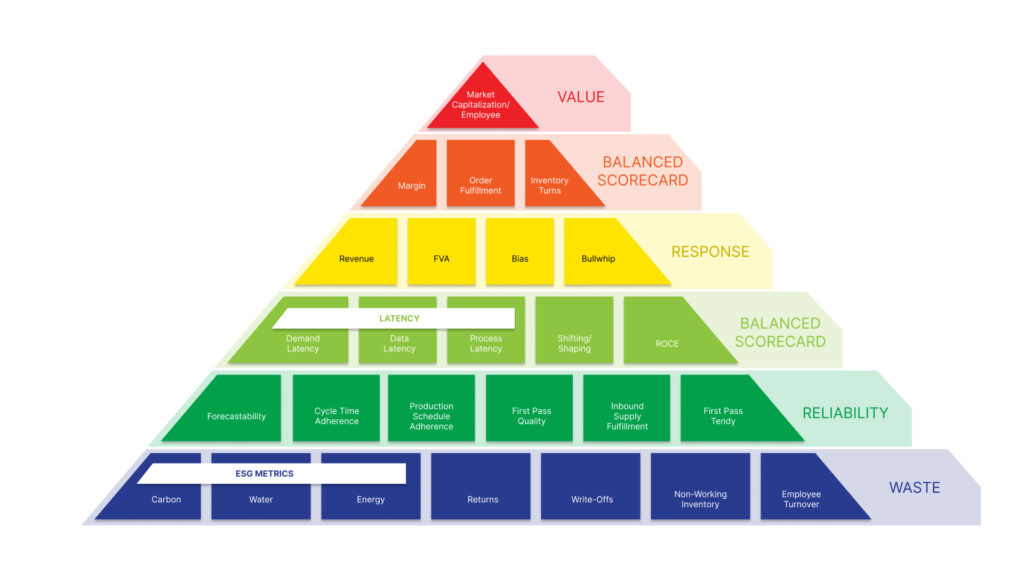

In the process, get clear on the goal. Learn that the traditional goals of supply chain focused on functional cost reduction sub-optimize the value of the firm. Embrace the principles of supply chain physics. Map your constraints by flow. Don’t just balance demand and supply volumes. Instead, understand and align demand and supply cycles to drive outcomes. Form and socialize your own hierarchy of metrics. For example, don’t focus on forecast error. Instead, analyze demand flow characteristics by demand stream to evaluate Forecast Value Added (FVA), forecastability, and bullwhip impact. Design your supply chain with a focus on the form and function of inventory. Here is the metrics framework that I am using at present in my outside-in classes.

Good luck in your journey. Let me know how I can help.