In the process of compiling the Supply Chains to Admire report for last year’s Supply Chain Insights Global Summit, the research team at Supply Chain Insights calculated the rate of supply chain improvement of companies by industry for the periods of 2006-2013 and 2009-2013. We wanted to see which companies were driving the fastest rate of improvement on the supply chain metrics that matter. We studied this pre- and post-recession.

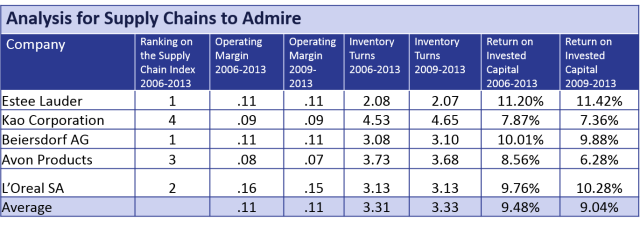

To validate our assumptions, we shared the data with supply chain leaders to get their feedback. In this process, we asked L’Oréal to comment on how they drove greater improvement than their peer group in cost and Return on Invested Capital (ROIC) in the cosmetics and beauty category. We compare the results in Table 1.

Note: The Supply Chain Index is a methodology to gauge supply chain improvement. Supply Chain Insights developed the Supply Chain Index in 2013. We find it is relatively easy to drive supply chain improvement if you are a low performer like Estée Lauder. However, it is tougher for an industry leader like L’Oréal. Note that they are pushing progress faster than their peer group and outperforming in all areas except inventory turns.

If L’Oréal had performed above the industry sub-segment for inventory turns, they would have made the list for the Supply Chains to Admire for 2014.

Table 1. Supply Chain Results Beauty Category

I am currently collecting case studies in supply chain leadership for my next book, Supply Chain Leadership Matters, to publish in 2016.

Richard Markoff is L’Oréal’s Corporate Director of Supply Chain Standards, based in Paris, by Barry Stewart, of L’Oréal Canada. After reviewing the results of the Index and the work that we are doing for our third book Supply Chain Leadership Matters, Richard agreed to coordinate a joint interview with the global head of Supply Chain, Emmanuel Plazol.

Richard Markoff is L’Oréal’s Corporate Director of Supply Chain Standards, based in Paris, by Barry Stewart, of L’Oréal Canada. After reviewing the results of the Index and the work that we are doing for our third book Supply Chain Leadership Matters, Richard agreed to coordinate a joint interview with the global head of Supply Chain, Emmanuel Plazol.

Richard has worked in Operations and Supply Chain for L’Oréal for over 20 years, starting in Canada, followed by roles in France and the United States. His experience spans the entire value chain from supplier relations through industrial planning, distribution to customer service and collaboration. He is now based in Paris and serves as Supply Chain Standards & Audits Director, helping to drive L’Oréal’s supply chain excellence through definition and communication of best practices. A Canadian citizen, Richard has a degree in Chemical Engineering and an MBA in Supply Chain Management.

Emmanuel has been working in Supply Chain for L’Oréal for over 20 years, starting in France followed by 10 years in New York where he led the Supply Chain for L’Oréal North America. Emmanuel returned to Paris 3 years ago to head the Corporate Supply Chain for L’Oréal. His experience spans the entire value chain.

Emmanuel has been working in Supply Chain for L’Oréal for over 20 years, starting in France followed by 10 years in New York where he led the Supply Chain for L’Oréal North America. Emmanuel returned to Paris 3 years ago to head the Corporate Supply Chain for L’Oréal. His experience spans the entire value chain.

Here I share their story.

At a high level, L’Oréal sells products in 130 countries with annual sales of €23 billion globally. The company operates 153 distribution centers and 39 manufacturing locations. The company has a strong commitment to the environment with significant reductions of carbon, waste, and water by internal teams over the past ten years.

Worldwide, there are 7,500 supply chain professionals. The organization is very matrixed, and both Emmanuel and Richard agreed that it is a unique culture. Each leader reports to two or three ‘bosses’. The goal is to have local talent. They find people with a passion for beauty (This is something that every gal appreciates). In the process, there is a heightened focus to find people with strong communication and influence skills.

The complexity in the business is high. Within the last 12 months, 50% of the L’Oréal products were new introductions. The Company is pushing growth at a rate of 3-4%. The strategy is to grow in new markets, widen channel distribution (deep trade programs), and build an e-commerce channels. As a result, the rhythms and cycles of the supply chain are faster than ever before. For the supply chain leaders, the lines between channels are blurring.

Defining Supply Chain Excellence.

When I asked Emmanuel to define Supply Chain Excellence, he responded, “This is a good question. My goal is to be integral to the business. We have customers. We have sales and finance teams and supply chain people. We win when we work together to focus on customer service. If we are successful, we will be the preferred partner of beauty products in our business.”

The company has a stretch goal to deliver higher service levels than ever before. Within the last eight months, both Richard and Emmanuel believe that they made substantial progress, and as a result, within the organization the commercial teams are more open to partnering. The team built credibility by managing cost and inventory while driving higher levels of customer service.

When asked how this happened, Emmanuel responded, “It has been about conscious choice and changing the mindset of the organization. It is this awareness that we changed drastically. Three years ago, the supply chain was something you had to have. Our concern was if we do not change the mindset, we would not deliver. So we asked ourselves, “What does it mean to deliver the right service? What does it mean to have the general management recognize us as a business partner? We built a road map from there.”

As we talked, I loved the stories. One example was the journey to improve forecast accuracy. Over the last five years, L’Oréal improved forecast accuracy by 11%. They train their teams every two years, and they believe that it is about the execution of successful programs, not tools. The CEO is very supportive. When a country struggles to deliver on the forecast accuracy goal, he will even send a personal note to the region!!!

To make these accomplishments, they focused on culture and talent development. They changed the profile of the team, including senior executives in each region. The goal was to include the supply chain in decisions of how they did business. Bringing people with the right approach with the customers and the sales people and showing that the supply chain helped to build the guiding coalition.

How Have You Driven Costs Faster Than Your Peer Group?

The focus is on executing the road map. Both recognized that It takes time to put in an organization. The right organization is close to the markets and connects the right information to the factories. The focus is on a customer-driven road map. The design is for processes for end-to-end Sales and Operations Planning (S&OP), and adding new master data tools. When it comes to the reduction of costs, the focus is on cost to serve. Only 1% of companies have successfully implemented cost-to-serve analysis. When asked how, the response was, “If you show a General manager that his sales is not performing, and the cost to a customer is out of control, it helps to get things back in line. We focused on inefficient orders, reducing backorders and eliminating point-of-sale materials.”

Understanding the Culture.

Flexibility is part of L’Oréal’s DNA. The organization moves rapidly based on the needs of its customers. The goal is to build an organization for life and embrace entrepreneurship. They adapt by region. For example, the luxury division in Japan does not have the same needs as the customer service division in Brazil. The goal is to do different, well, based on a common backbone of capabilities.

“The Body Shop is a standalone division. As of today, every division that we have, they are mature by themselves. Luxury division has one catalogue and the same product globally. The mass market is more regional…once by country. Globally, for all of these divisions you need to understand the needs of our customers and the constructs of the factory.”

When asked to comment on the cultural DNA, they responded, “We take the time to communicate what you want to do. It takes a concerted effort to make sure that everyone understands what they need to do. Sometimes people will go faster building an organization, and it is important to ask yourself, ‘Why are we organized this way?’ It is an environment of continual change. For example, it is difficult to implement new tools on an old organization. When we move to a more modern process, or organization, we need to bring new tools to understand that everyone knows what they do. It is very important to bring people with you. You need to understand what they do, and the tools they use, and ensure they understand their role in the global organization.”

L’Oréal does not work with rigid things. The cultural DNA is more network and the people. Richard and Emanuel remind themselves and their organization continually that L’Oréal is a marketing company, and that they cannot forget that they are foremost a marketing company. They commented that they continually ask, “How can we serve the brand? What do we do to fuel the brand?” Their goal is to have everyone actively engaged, while encouraging everyone to follow their passion and conviction, while being resilient, but not stubborn. Everyone in the organization has many degrees of freedom. If you have a good idea at L’Oreal, you can try it; and if it works, the company will celebrate the win. As a matrixed organization they take advantage of the non-linearity. The belief is that it allows the team to think about all of the different aspects of the organization.

When asked about Supply Chain 2020, they responded, “To succeed, we need to put a lot of passion into our positions. It is not only about time, but it is your intuition and your gut. If you are passionate then other people will follow you. 2020? The team for me is the most important thing. Our customers drive the design of our organization. L’Oréall’s organization shifts as customers morph. In a few years, the segmentation that we have will be different. Retail, e-commerce, and Omni-channel and multi-channel, and the organization is ready for that. We can anticipate this change, but what is next in digital? The consumers of our product are in the computer. I am still outside the computer. The more digital we are, the more information that people want on our products. Supply chain is integral to the business strategy.”

My Take:

Without a doubt, L’Oréal is a supply chain leader in the beauty category. The cultural dynamics and descriptions contained in this case study speak volumes of how a supply chain leader closed the gap between operations and commercial teams and led a supply chain transformation. Some of the elements are remarkable. For example, only 1% of companies effectively implement cost-to-serve analysis; and it is the first time, in my history as an analyst, that I know of a CEO sending personal letters to the divisions on forecast accuracy. The performance improvements over the past six years speak volumes. Bravo! C’est fantastique! It makes me love my favorite brand of Kerastase that much more!

To appreciate the culture, here are some videos of L’Oreal.

https://www.youtube.com/watch?v=McCUVz-5Ygc

https://www.youtube.com/watch?v=mEZ8crXysnE

_______________________________________________________________________________

Lora Cecere is the Founder of Supply Chain Insights. She is trying to redefine the industry analyst model to make it friendlier and more useful for supply chain leaders. Lora has written the books Supply Chain Metrics That Matter and Bricks Matter, and is currently working on her third book, Leadership Matters. She also actively blogs on her Supply Chain Insights website, at the Supply Chain Shaman blog, and for Forbes. When not writing or running her company, Lora is training for a triathlon, taking classes for her DBA degree in research, quilting for her new granddaughter, and actively taking ballet.

Turn Off the Fog Machine: Move Past Groupthink to Drive A Positive, Data-Driven Narrative

In this blog post, Lora Cecere, Founder of Supply Chain Insights, asks if our current focus on doom and gloom is a fog machine, and a barrier to driving improvement.