This week I am busy packing. It is the same feeling that I had as a child getting ready for camp. For the next 18 weeks I will be in the air. I will be speaking and working with clients in wonderful locations in Brussels, China, Germany, London, Mexico, Peru, and South Africa. In the process I needed a visa for China, and I wandered into an old-fashioned photo shop to have my picture taken for the visa application.

This week I am busy packing. It is the same feeling that I had as a child getting ready for camp. For the next 18 weeks I will be in the air. I will be speaking and working with clients in wonderful locations in Brussels, China, Germany, London, Mexico, Peru, and South Africa. In the process I needed a visa for China, and I wandered into an old-fashioned photo shop to have my picture taken for the visa application.

I love photography, and mused as I walked into the shop on that rainy day in Philadelphia. I smiled when I saw that they still printed film the old-fashioned way. When I asked the owner how long it would take to process the pictures for my visa she said, “It will take a while. Probably three to five minutes. Why don’t you go have lunch?” I gave her a stare in disbelief. At one time a three to five minute response would be seen as immediate. I even remember when the overnight processing of film was considered quick. Now the expectation is immediate or real-time.

As I drank a cup of coffee and waited, I reflected on the article I had just completed for the Institute of Supply Management. At their request I wrote on the digital supply chain. I cringed when I got the assignment. Digital supply chain is such a buzzword. One of my friends in consulting markets the concept by a direct-mail campaign of mailing personal drones in special wrappers. When he told me I laughed and said, “That is so lame! The digital supply chain is about SO much more than gadgets.”

I hate buzzwords and try to sidestep hype, but as I held my mug tight in my hand on a cold Philadelphia day, I thought more about the photo shop experience. I reflected. Very little is the same within a photography store as compared to five years ago. No one waits for a picture. Yet, within the supply chain, everyone waits for data and insights. One of my clients waits four days for a custom report. At another client there are 80 ERP systems, and the supply chain team cannot see across instances. It is sad, but true.

Supply chains do not move in the cadence of the market. Leaders know that massive change in supply chain processes is coming but they do not know how to get started. This is the goal of this blog.

Reflection

Five years ago the buzz in marketing was rampant. The talk was all about digital marketing. Today marketing is just marketing. The term digital was dropped. The reason? Digital media and technologies were quickly absorbed into marketing processes and redefined the norm. Few companies speak of digital marketing now: it is just assumed.

In supply chain, leaders are just starting to think about digital. A frequent question from my clients is, “What is a digital supply chain process?” My answer is that a digital supply chain process uses new technologies to define processes to sense, respond and orchestrate bidirectionally from market to market (from the channel to supplier networks). The processes move at the cadence of the market. This is a very different definition than the traditional supply chain practices that are often touted as “best practices.” Supply chain practices are almost 35 years old, and they are slow to change.

Let’s start by examining the differences. I see five primary, but pervasive, shifts.

- Sensing. Traditional supply chains do not sense. They respond. The response is usually based on history. Despite all of the investment in sensors–RFID, PLC(s), GPS, telematics–most are not used in day-to-day supply chain processes.

- Outside-In. Historic processes are inside-out, rooted in transactions. Digital processes are outside-in, focused on market opportunity and risk. This requires the mapping and rethinking of supply chain processes. The digital supply chain transformation requires rethinking the basics.

- Cross-Functional and Horizontal. Historically, supply chain processes were functional focused on make, source and deliver. The digital supply chain is cross-functional and aligned market-to-market. The flows are from the customer’s customer to the supplier’s supplier.

- Quick. Nimble and Responsive. Traditionally, supply chain technologies are batch processes. As a result, analytics are usually based on historic data with outputs having a one- or two-day lag. The digital supply chain enables the use of market data at the cadence of the market. The supply chain no longer needs out of step with the shopper or the supplier.

- Network Response. While the traditional supply chain focus is on the implementation of enterprise applications, the digital supply chain is outside-in, based on network sensing and adaptation. While the last decade focused on the automation of the enterprise, the next decade will focus on the digitization of the network.

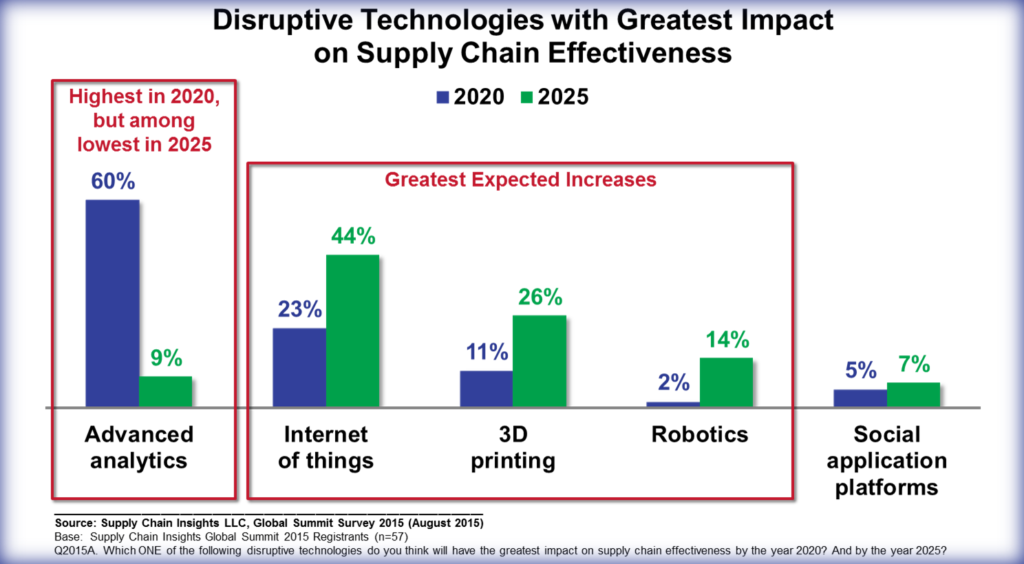

Figure 1. Adoption of Digital Technologies

How will it happen? What are the important digital technologies? There are many. The confluence of technology is the driver. It is not one technology: it is many. This includes 3D printing, robotics, the Internet of Things (IOT), Sentiment Analysis, Cognitive Learning, and Supply Chain Operating Networks using canonical many-to-many data models. As shown in Figure 1, while the initial focus is on analytics, in the next ten years digital processes will develop based on a confluence of technologies. It will not look the same everywhere. The processes will evolve based on the drivers within the value network.

In my speeches on the evolution of the digital supply chain, leaders ask me , “How do I get started? What should I do as a leader to accelerate value?”

My advice is to throw away any concepts of “best practices” and embrace “new and emerging technologies.” Traditional IT projects of three letter acronyms (ERP, APS, CRM, SRM) fueled the evolution of the current state. However, the adoption of digital processes requires rethinking of the project implementation as well. Let’s examine the basics. In the traditional process design, the start of a project was the mapping of “as is” and “to be” processes. The next step was usually the implementation of a large project. In contrast, test-and-learn principles drive digital evolution. Start small, learn, and then evolve. The testing of digital processes is best leveraged by a small cross-functional team led by a line-of-business leader. Charter a scrappy team of diverse and talented people to challenge the status quo.

I encourage business leaders to self-fund their projects. How to do this in the face of severe cost-cutting pressures? Many of my clients save 5-10% of funds from their continuous improvement projects and self-fund their efforts. Gradually their teams evolve their understanding of what is possible.

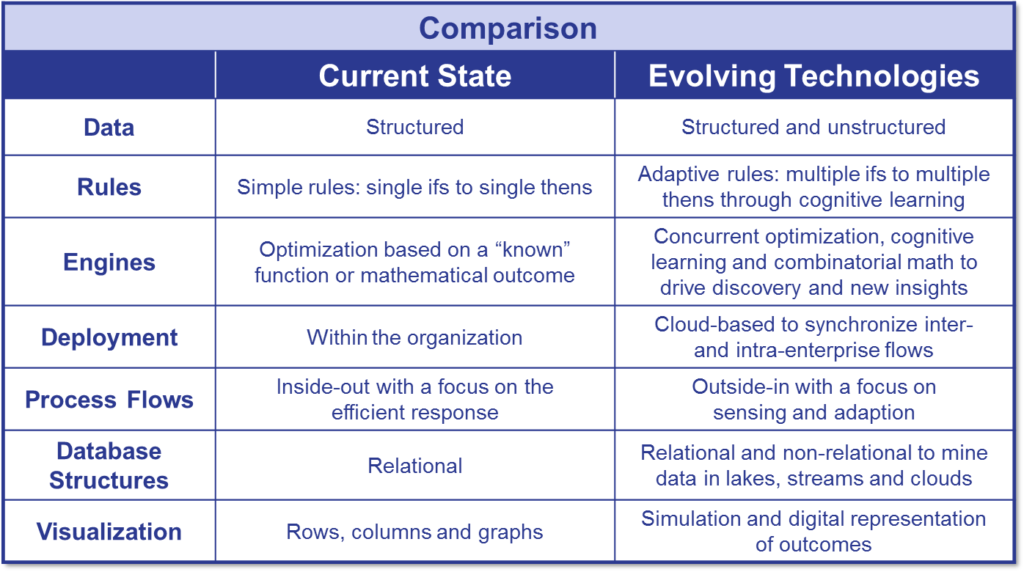

The next step is education. The technologies, terms and process definitions are new. As shown in Table 1, most organizations think in the terms of transactional, or structured, data. The use of unstructured data is new and the analytics to mine and harvest unstructured data will take time to evolve. A good place to start is the mining of sentiment data from customer call centers, rating-and-review information, and social media. After mining the data, form cross-functional review groups to understand the true “voice of the customer.” At Dell, Lenovo and Whirlpool these are weekly meetings. Then start mapping the processes outside-in to capture the voice of the customer and power customer-centric processes.

Test and learn using new forms of visualization and pattern recognition. Look for cloud-based deployments that support a heterogeneous environment. Challenge the teams working with the data to give you one new insight a week. Build sensing capabilities: look for the trends that you do not know.

Over time, build capabilities for streaming data (the data infrastructure to support the Internet of Things), rules-based ontologies to support cognitive learning, and pattern recognition in network sensing. Take your time. These are new concepts. As you learn, brainstorm with the group to design new digital outside-in processes.

Ask yourself, “Where is my opportunity? Is my opportunity in the area of digital manufacturing? “ (The use of Internet of Things and 3D Printing to transform manufacturing.) Digital logistics? (The use of GPS, telematics, and cognitive learning to build logistics systems that sense and adapt.) Digital sourcing? (The use of new network technologies to sense and manage supplier relationships to ensure ethical and reliable sourcing.) Digital path to purchase? (The automation of the moments of truth in the buying cycle to decrease demand latency and better sense shopper and consumer demand in real-time.) Start with the goal in mind and focus on the greatest value proposition.

Table 1. Characteristics of the Digital Evolution

Along the way, avoid hype. While consultants will come and talk to you about big data, and digital transformation, sidestep buzzwords. Make your transition real and powerful. No doubt about it, we are in the middle of change. However, the evolution of supply chain processes will take time. It is not an evolution. Digital supply chain processes are a redefinition. It is both promising and challenging. I believe that we are at the beginning of a 15-year evolution. Good luck with your journey. I hope to see you in my travels.

I am currently working on the agenda for the Supply Chain Insights Global Summit. Learn more about these concepts there and network with peers.

About Lora:

Lora Cecere is the Founder of Supply Chain Insights. She is trying to redefine the industry analyst model to make it friendlier and more useful for supply chain leaders. Lora has written the books Supply Chain Metrics That Matter and Bricks Matter, and is currently working on her third book, Leadership Matters. She also actively blogs on her Supply Chain Insights website, at the Supply Chain Shaman blog, and for Forbes. When not writing or running her company, Lora is training for a triathlon, taking classes for her DBA degree in research, knitting and quilting for her new granddaughter, and doing tendu (s) and Dégagé (s) to dome her feet for pointe work at the ballet barre. Lora thinks that we are never too old to learn or to push for supply chain excellence.

Lora Cecere is the Founder of Supply Chain Insights. She is trying to redefine the industry analyst model to make it friendlier and more useful for supply chain leaders. Lora has written the books Supply Chain Metrics That Matter and Bricks Matter, and is currently working on her third book, Leadership Matters. She also actively blogs on her Supply Chain Insights website, at the Supply Chain Shaman blog, and for Forbes. When not writing or running her company, Lora is training for a triathlon, taking classes for her DBA degree in research, knitting and quilting for her new granddaughter, and doing tendu (s) and Dégagé (s) to dome her feet for pointe work at the ballet barre. Lora thinks that we are never too old to learn or to push for supply chain excellence.