With the evolution of technology, we have an opportunity to redefine work and improve outcomes from supply chain planning. This can only happen if we acknowledge the gaps in current processes. Current supply chain planning processes are broken and degrade value.

The second barrier is the evolution of vision: cutting through the current gibberish to drive adoption.

Problem Statement

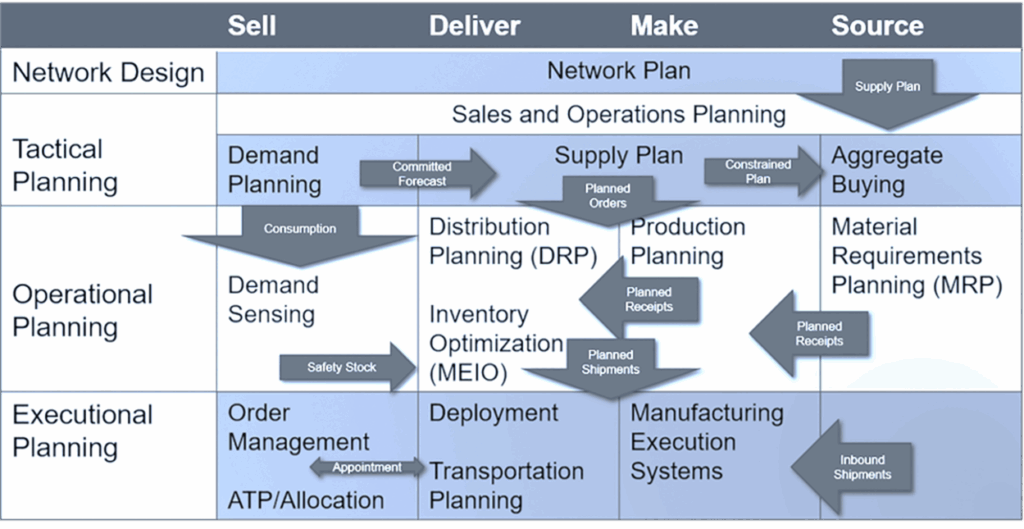

Today, we have historical platforms as defined in Figure 1–a series of processes based on the output of optimization models linked together–and the infancy of Native AI platforms that combine machine learning, Large and Small Learning Models (LLMs and SLMs), and forms of AI (agentic, deep learning, reinforcement learning, etc) with statistics. We are straddling two worlds.

Planning processes, as currently defined, are functional, linear, and often not fit for purpose. We speak of end-to-end planning, but this is not the reality. The reason? There is no unified data model to synchronize the flows. As a result, planning systems (historical definition in Figure 1) are a good fit for a small regional process company, but not for a large global multinational.

Figure 1. Traditional Supply Chain Planning Taxonomy. Each box contains a model and a set of engines that drive an optimization output, which is then linked to the next model.

Without good options, the global multinational company struggles and is often forced to build custom code.

The reasons? There are many.

- Cost. The systems are costly to purchase and implement. Most solutions are priced based on the number of users or corporate revenue which increases the cost to deploy expnentially.

- Increased Variability. Traditional statistical models are not equal to the rise in variability. Few companies are using machine learning to understand the patterns of key supply chain parameters like lead time, order latency, conversion rates, cycle times, and commodity prices. For a global company with many factories, products, and locations, this planning master data is constantly changing, but current system deployments use fixed factors that are out of sync with global markets.

- Functional Optimization. In historic platforms, each model has a functional objective function. Functional optimization improves functional costs, but will often result in higher total costs. (The supply chain is a complex, non-linear system.) As a result, it is difficult to align source, make, and deliver model outcomes together to improve operating margin.

- Labor Intensive. As companies moved from regional to global, the number of planners grew exponentially. (One company that I work with went from 200 to 1600 planners over the course of the past decade.) With market uncertainty, companies are attempting to improve white collar productivity. Reducing the number of planners is a high priority. (However, I would like for planning effectiveness to be an even greater priority.)

- Lack of Governance. Most systems were installed without clear governance. Few companies are clear on what makes a good plan, and the roles of the global, regional, and divisional teams are not clearly defined in the project implementation.

- Misuse. Companies are trying to forecast items that are not forecastable and plan for materials when market demand is unknown. Each of these common scenarios do not fit well into conventional models. In my training classes, we find that only 50% of items are forecastable at an item/location level– and the deployments lack the model selection, hierarchical definition, and engine options to improve outcomes. In addition, most companies degrade the forecast (measurement of FVA) with their current processes.

- User Experience. Usability is low, leading to the use of spreadsheets for 90% of supply chain decisions.

Is Orchestration the Answer to Redefining Work?

As I scan my LinkedIn stream, no doubt about it, the term “orchestration” is rising in popularity. Used often and seldom with definition, the current use of the term does not match my definition leaving me scratching my head. It is being used interchangeably for data, process, and AI agent collaboration. The use cases vary by LinkedIn profile. In the feed this morning was improvement of rules-based consumption through in-memory planning, harmonization of data, synchronization of agent deployment and process trade-offs. (Direct quotes are listed in the Appendix.)

Why is this of interest? As we redefine work through the use of new forms of technology, I believe that the planner becomes the supply chain orchestrator. In the redefinition of work, in the new job description, planning orchestration includes data wrangling, agent governance, leading innovation initiatives, and defining process synchronization/corporate planning governance.

I believe there is an opportunity to define self-service planning for business leaders. With the use of large language models and unstructured data mining, business leaders can have greater access to data enabling self-service by business leaders through role-based interfaces and workflow. (Most of the focus of current technologists is on the planner as a user.) With this redefinition of work, the planner is no longer trapped in endless meetings and data analysis. (Today’s planner has the lowest level of job satisfaction of anyone in the supply chain function.)

Today, we are in an awkward transition. Traditional planning providers are layering AI capabilities on top of historic taxonomies and waxing eloquently about improved value while native AI technologies are getting their sea legs.

Mistakes

As I read through the posts, I think that the industry needs to avoid the following pitfalls as we engage in this awkward dance between traditional planning platforms and the evolution of native-AI planning:

- Technology Focus. I frequent mistake I see is when a technology provider has a good idea, but focuses on technology for technology’s sake. For example, why is Gains marketing a composible platform supply chain planning platform? Versus a focus on improving outcomes? Or Kinaxis marketing Maestro versus sharing the benefit of the new architecture with the business buyer? Or o9 marketing the use of the graph for planning without clearly delineating the value of the graph in deployment. Each has value, but is not well-explained for the buyer.

- Gobblegook. Acronyms, made-up words, and marketing hype define gobblegook. The market is confused enough.

- Adaptation of Current Systems Versus a Focus on Redefining Work. A common approach is to put agent technology on top of existing architectures without addressing the current performance gaps of supply chain planning. I call this AI’ing Stupid.

- AI Everywhere; Yet Nowhere. In marketing pitches, AI is thrown around like the Parmesan on my pizza. Few companies clarify the differences between native-AI approaches and the use of AI on top of traditional supply chain planning.

- Confusion between Native-AI and Conventional Supply Chain Planning. All of the pitches sound the same. Technologists need to differentiate between native AI and the use of machine learning/agentic AI on top of conventional supply chain planning.

Next Steps

So, how do we evolve to outside-in processes while redefining our relationship with data, code, and models? The answer is evolving, but it starts with a clear vision of what is possible. This week, we kicked off three classes in our outside-in planning training, focusing on defining and implementing outside-in processes. It is exciting to see the learning.

Outside-in planning may not be the right approach for you, but I would caution that in deploying any form of planning, you need to be clear on what drives a good plan and focus on actualizing your vision. In the process, sidestep vague terms and push for clear definitions for terms like efficiency, agility, proactive, orchestration, and value. Getting clear on these terms is important to define outcomes.

Secondly, in the implementation of planning, align metrics and engine/model outputs to improve a balanced scorecard. Sidestep functional metrics–functional cost, OEE (Overall Equipment Efficiency), and labor costs–that diminish value.

Secondly, if you are reading this research, I would love your help to participate in research on the redefinition of supply chain platforms. My goal is to give to you through my writings when you give to me by filling out research studies. I will share the results openly through the research. Here is the link to share your insights. The survey is open to all–business users, technologists, and consultants. All respondent data will be shared confidentially without attribution.

Appendix: Orchestration Definitions in my LinkedIn Feed

One of the principles of academic research (learned through taking my DBA studies) is to start a research project with a literature search. This listing details the use of the term ‘orchestration’ from my LinkedIn feed this week.

In the analysis below, you can see that teams new to Agentic AI focus on the seamless collaboration of agents. While data scientists’ posts focus more on the orchestration of data: synchronization, harmonization, and driving interoperability. In contrast, supply chain practitioners’ focus is primarily on process synchronization and collaboration within workstreams to improve outcomes.

To start my research, I started by asking ChatGPT a number of prompts. One was the difference between orchestration and supply chain collaboration.

“Collaboration involves multiple participants working together and exchanging messages, while orchestration refers to a single entity coordinating and managing the interactions between different services or processes. Essentially, collaboration focuses on the interactions themselves, whereas orchestration centralizes control over those interactions.” Chat GPT, October 2025

Here are the direct quotes from my LinkedIn feed:

- ” Orchestration isn’t just about automating tasks—it’s about connecting people, systems and purpose so work flows with clarity, trust, and purpose.” Vivek, Venkataraman, Acheron Consulting, October 2025

- “Orchestration is the operating layer that keeps planning and execution in sync.” Kushan K Surana, Kinaxis, October 12, 2025

- “Orchestration is intelligent prompting, where humans, agents, and systems work together seamlessly through natural language.” Jag Lamba, Certa.ai, LinkedIn, October 2025

- “Orchestrate is about managing the big picture across the entire supply chain—setting goals, aligning teams, and making sure all the moving parts (planning, sourcing, delivering, etc.) are working toward the same strategy. It’s like the role of a coach who doesn’t play in the game but makes sure the team works together, follows the game plan, and adjusts when needed. For example, a smartphone company uses real-time data from suppliers, factories, and sales to shift production from one model to another if it sees higher demand or a delay in a specific component.” SCOR DS, 2024

- “Supply chain orchestration is SAP’s new AI-driven solution that brings true foresight into every part of the supply chain. It connects planning, logistics, procurement, and manufacturing so that potential risks can be identified earlier and decisions made faster and more confidently.” Andreas Thon, SAP, October 2025

- “Supply chain orchestration is a strategic approach that integrates and coordinates all processes, systems, and stakeholders across the entire supply chain to create a seamless, agile, and data-driven operation.“, Bhanu Nimraini, Kuehne and Nagel, LinkedIn, October 2025

- ” Orchestration isn’t just about automating tasks—it’s about connecting people, systems, and purpose so work flows with clarity, trust, and purpose.”

In summary, the word orchestration is used frequently with many different definitions. This is an example of the nuance that envelops the supply chain community, hindering progress and requiring teams to clearly define outcomes to make supply chain planning a success.